Reproducible tests of filter media under extreme conditions

Recently, GKN Sinter Metals Engineering in Radvormwald is testing the filter media under extreme conditions. In order to make this possible, GKN Technology Centre for Powder Metallurgy is equipped with Palas® MMTC 2000 EHF filter test rig, for developing new filters and then comparing with other filters in the market.

With more than 30 years of professional knowledge and advanced technology, Palas® has now become the market leader in the field of filter test systems, and is used by many well-known companies in various industries around the world for the quality control, characterization and development of filtration and separation systems. Reliable complete solution can meet almost all industrial needs in the world.

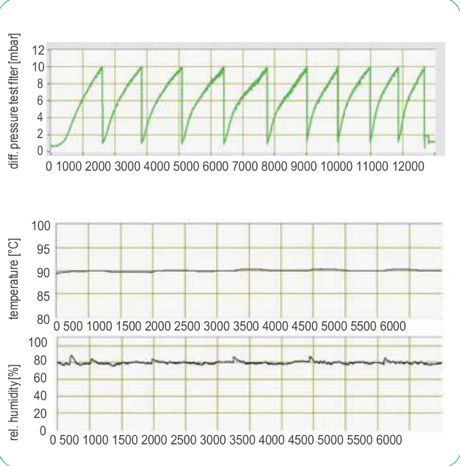

With the MMTC system, Palas® provides an ultra-precise and cost-effective test system for quality control and the development of cleanable filter media, and different test dusts can be used to test filter media. Palas® MMTC 2000 EHF filter test rig can test the filter media under extreme conditions, a maximum temperature of 250°C and an adjustable relative humidity of up to 80%, and offers high test result reproducibility.

Pressure loss, humidity and temperature curve under 80% relative humidity and temperature 90℃

Palas® MMTC 2000 EHF filter test rig is designed to be lightweight, simple and easy to operate, and meets the VDI 3926 standard. It can be widely used in many fields such as the cement industry, wood processing industry, pharmaceutical industry, and chemical industry, etc.