With the Chinese New Year just around the corner, don’t forget to include some good masks in your shopping list for the festival as protection against the pandemic! As the officially-recognized mask testing instrument manufacturer in Germany, Palas® test rigs have made their way into the test facilities of renowned Chinese manufacturers of filters and masks to guarantee quality and product safety.

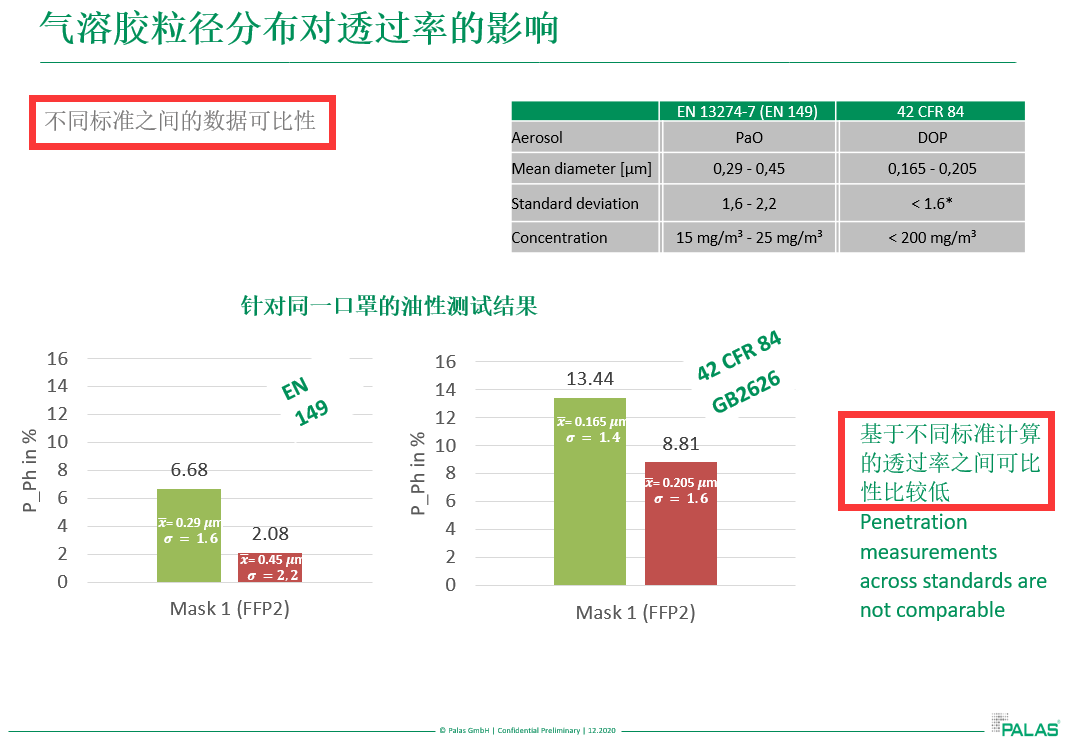

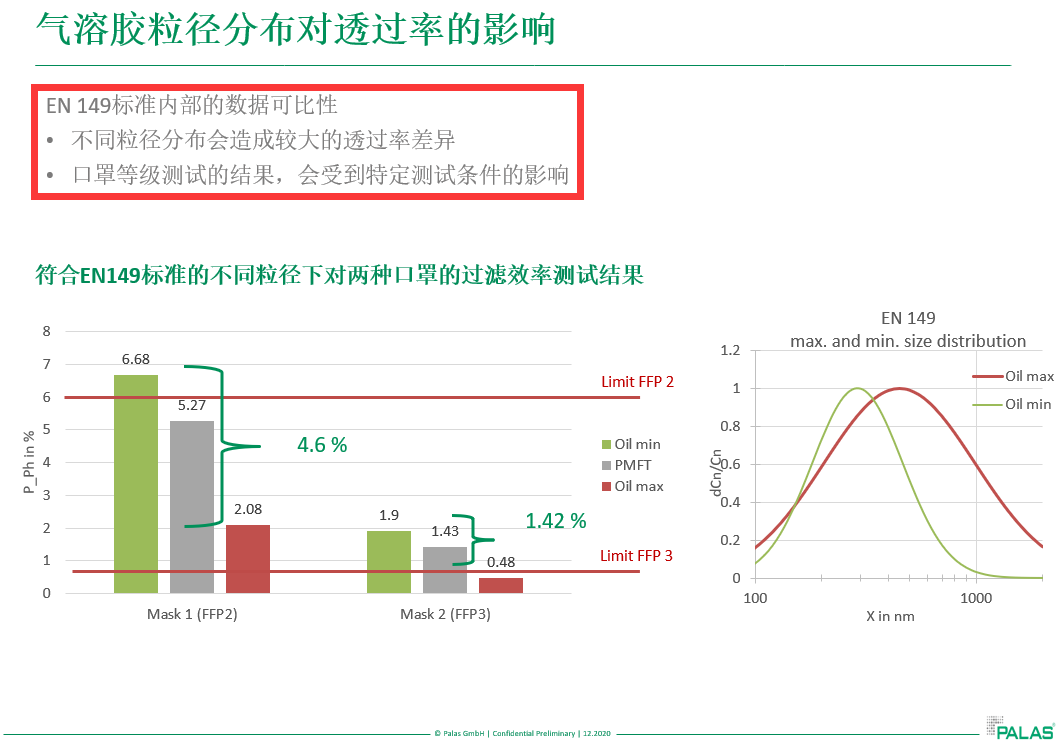

In the context of the epidemic started from last year, mask manufacture has become a hot topic of media discussion. Classification based on different standards, such as FFP 1-3 and KN95/KP95, and national standards vary in terms of test conditions and tolerances, resulting in different test results for mask filtration efficiency. Test results are not comparable across standards given the changing particle mass concentrations or particle-size distributions. The reason is that different standards require different measurement techniques and testing conditions. Filtration efficiency calculated on the basis of mass concentration is determined by the large-size particles in the aerosol, which means the penetration rate of small particles will be significantly higher. Even with comparable data within the EN 149 standard, differences in particle size distribution and dust concentrations can result in varying penetration rates, which may affect mask classification. Faced with many challenges, how should we deal with it?

Palas® PMFT mask filtration efficiency test rigs are designed to help testing institutions and mask or melt-blown cloth manufacturers face challenges! The Palas® PMFT system enables testing of respiratory masks better than the national and regional standards in the EU, China and the U.S., and provides filtration efficiency tests in accordance with EN149, NIOSH (42CFR84), GB2626 and ASTM F2100 to support export operations. It supports a selection of photometric modes according to requirements, and is equipped with two aerosol generators for oil and sodium chloride. It also enables testing of masks and flat-sheet filter media, offers a maximum flow rate range of 450 l/min, and supports simulated breathing resistance testing. For manufacturing industries, PMFT 1000 series products can also provide information on the filtration efficiency of particulate matter under various particle sizes based on filtration efficiency testing and analysis, which helps the R&D department continue to optimize products. Under the current epidemic, it is particularly important to!

How well do you know about mask standards in different countries? Let us take a look at masks and standards. We share with you the detailed explanation and comparison of PMFT applying to the standards of different countries:

PMFT fulfils Chinese Mask Standard GB2626

Several major standards for Chinese masks are GB2626-2019 respiratory protection self-priming filter particulate respirator, GB/T32610-2016 technical specifications for daily protective masks, YY/T0969-2013 disposable medical masks, YY0469-2011 medical surgery Masks, GB19083-2010 technical requirements for medical protective masks. According to the level of filtration efficiency, the respirator filter element can be classified into 90 (KN90, KP90), 95 (KN95, KP95) and 100 (KN100, KP100). The numbers indicate the filtration efficiency. Category KN is tested with sodium chloride particles, whereas Category KP is used to filter oil particles. The revised version, GB 2626-2019 Respiratory Protection – Non-Powered Air-Purifying Particle Respirator, was officially released on 31 December 2019 and became effective on 1 July 2020. The new standard includes additional requirements for respirator materials and leakage testing methods for removable parts. The test flow rate for this standard is 85L/min. The standard specifies breathing resistance as inspiratory resistance not exceeding 350pa and expiratory resistance not exceeding 250pa.

GB2626 Mask Classes

GB2626 Mask Classes

PMFT fulfils EU Mask Standard EN149/EN13274-7

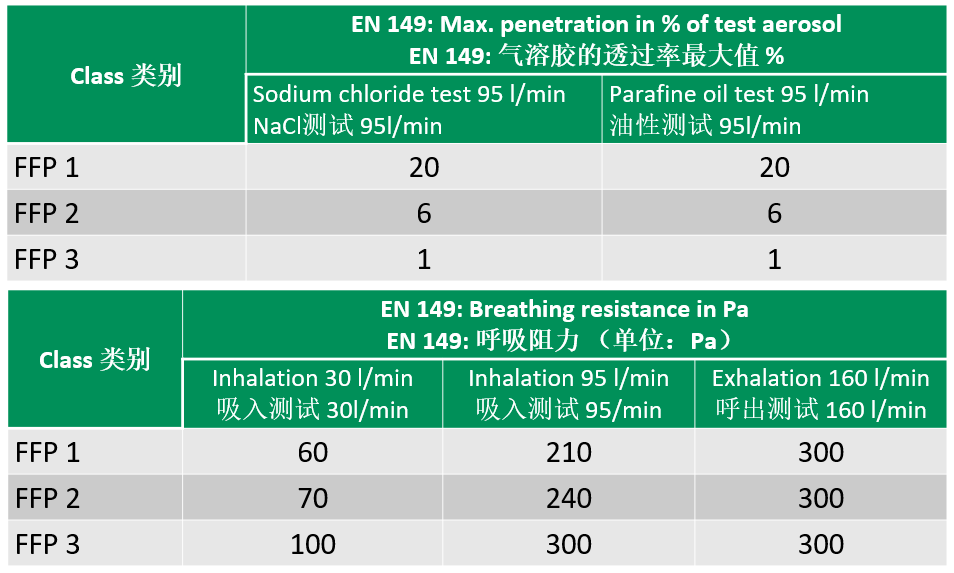

The European Union has harmonized mask standards (Conformité Européenne, CE) into BSEN140, BSEN14387, BSEN143, BSEN149 and BSEN136. In particular, BSEN149 Respiratory Protective Devices – Filtering Half Masks is widely used to protect against particles. Three classes of such particle half mask have been defined, namely P1 (FFP1), P2 (FFP2) and P3 (FFP3) (FFP = Filtering Face Piece), according to their filtering efficiency. FFP1 filters at least 80% of airborne particles, FFP2 at least 94% and FFP3 at least 97%. FFP2 masks have very similar filtration efficiency as medical protective masks, KN95 masks and N95 masks. The test flow rate for this standard is 95L/min.

EN 149 contains a number of tests. PMFT1000 can be used to test the filtration efficiency based on the EN149 standard. The EN149 filtration efficiency test method is similar to EN13274-7. EN 13274-7 is aimed at testing the filtration efficiency of protective masks. Since PMFT not only provides filtration efficiency data for mass concentration in the entire particle size range, but also filtration efficiency data for different particle sizes, using PMFT1000 test masks can obtain more information than EN13274-7 requires.

EN149 Mask Classes

EN149 Mask Classes

PMFT fulfils US Mask Standard NIOSH (42CFR84) and ASTM F2100

The U.S. National Institute for Occupational Safety and Health (NIOSH) standard, which classifies filter material and filtration efficiency of masks, is well recognized worldwide. It provides for three levels of filter, namely N-, R-, and P-series filters, each with three categories of resistance to filter efficiency degradation. N-series filters should be used for non-oil aerosols, including coal dust, cement dust, acid mist, microorganisms and droplets from talking or coughing. The current rampant smog pollution mostly includes non-oil suspended particles. Oil particles refer to oil fumes (from cooking), oil mist, asphalt fumes, etc. R- and P-series are used to protect against non-oil and oil particles. Compared to R-series, P-series filters can be used for a relatively longer period of time, depending on the manufacturer’s label. A filter marked N95 would mean an N-series filter that is at least 95% efficient and is tested for tightness on the wearer’s face to ensure that air can pass in and out through the mask when it is close to the edge of the face. Only masks that pass the test are certified N95 masks. N95 masks are not the same as medical protective masks, which are required to meet N95 filtration efficiency and have surface moisture resistance and blood barrier capabilities.

ASTMF2100 standard: a medical standard which classifies masks into three levels: low protection (level 1), medium protection (level 2) and high protection (level 3). The higher the level, the better the protection. Level 1 and Level 2 masks are usually called procedure masks; Level 3 mask, or surgical mask, can be used inside the operating room. When exposure to viruses is particularly high, higher levels of protection should be chosen. A Level 1 mask, which blocks 95% of bacteria and particles, is sufficient to protect the average community user, even if it only meets the low protection standard. A Level 2 or Level 3 (medium to high protection) mask blocks at least 98% of bacteria and particles, with a differential pressure of just under 49.0 Pa/cm, which is less stringent than the low protection standard, as it’s difficult to achieve better protection while maintaining the same breathability. The main difference between the medium and high protection standards is that the latter (Level 3) requires a higher level of ability to block liquids.

Through the introduction of the above mask standards, we believe it will be helpful for you to purchase masks that meet the standards. The Spring Festival holiday is getting closer. Whether you are celebrating the New Year on the spot or going home, wear a mask correctly, maintain social distance. With all the helps and supports from different parties, we can spend a special Spring Festival holiday safely. Finally, Palas® instrument wishes you a happy and prosperous Year of the Ox!

Reference:

GB 2626-2006 Respiratory Protection – Non-Powered Air-Purifying Particle Respirator

YY0469-2011 Surgical Mask

GB19083-2010 Technical Requirements for Protective Face Mask for Medical Use

GB/T 32610-2016 Technical Specification of Daily Protective Mask

TAJ1001-2015 PM2.5 Protective Mask

NIOSH Standards (Title 42 CFR Part 84)

EN149: 2001+A1-2009

EN14683-2014 ASTM F2100-2004

Palas® China will arrange a series of online webinars both in English and Chinese for PMFT mask filtration efficiency tester, MFP series filter material filtration efficiency tester, Promo® and Aerosol Generator and Dilution system, and Fidas®, AQ Guard air quality detector, U-SMPS scanning electric mobility particle size spectrometer, HMT testing system, and many other solutions. If interested in the webinars for our products, you are more than welcome to register on our official website and get the latest webinar plan!

Register online now to participate in our webinars if interested

| Date | Day of week | Time | Topic |

| 2021/3/5 | Friday | 14:00 – 15:30 | MFP Webinar “Advanced” |

| 2021/3/12 | Friday | 14:00 – 15:30 | SMPS Webinar “Basics” |

| 2021/3/16 | Tuesday | 15:00-16:30 | Fidas® & AQ Guard & Cloud Droplet Analyst & Promo® 2000 & SMPS Application |

| 2021/3/19 | Friday | 14:00 – 15:30 | PMFT Webinar “Basics” |

| 2021/3/26 | Friday | 14:00 – 15:30 | Fidas® & AQ Guard Webinar “Basics” |

| 2021/4/2 | Friday | 14:00 – 15:30 | Promo® & Aerosol Generator & Dilution system Webinar “Basics” |

| 2021/4/9 | Friday | 14:00 – 15:30 | SMPS Webinar “Basics” |

| 2021/4/16 | Friday | 14:00 – 15:30 | MFP Webinar “Basics” |

| 2021/4/23 | Friday | 14:00 – 15:30 | Fidas® & AQ Guard Webinar “Basics” |

| 2021/4/30 | Friday | 14:00 – 15:30 | PMFT Webinar “Basics” |

| 2021/5/7 | Friday | 14:00 – 15:30 | HMT 1000 Webinar “Basics” |