As global concern for air quality gradually increases, the issue of harmful particulate matter (PM) emissions has become a hot topic in the environmental and health fields. The Institute of Vehicle System Technology of the Karlsruhe Institute of Technology uses advanced technological tools, in particular the Palas® Promo scattered-light aerosol spectrometer system, to study in depth the phenomenon of particulate emissions when tires come into contact with the road surface. By combining factors such as load condition, tire type and ambient temperature, they reveal the effect of different conditions on the particulate emissions from tire pavement.

The choice of the famous university research team

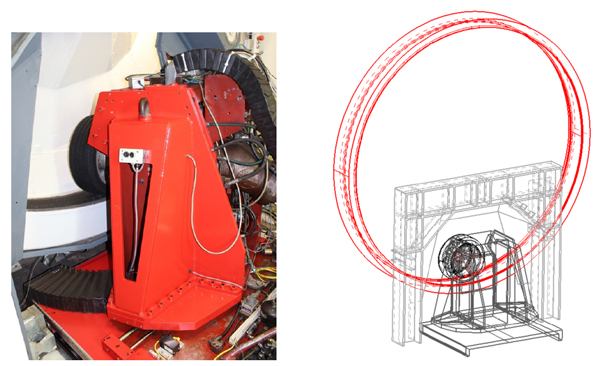

The Karlsruhe Institute of Technology (KIT) is Germany’s longest-established university of technology and a large research centre, ranked sixth in Europe for overall academic impact. In this study, the institute’s technicians used an internal drum test bench to test and analyse particulate emissions from tires in contact with the road surface. The test rig was equipped with a real road surface and upgraded to measure particulate matter in real time. To conduct the various tests, the researchers chose different types of tires, including summer, winter and all-season tires, and tested them at different ambient temperatures. By studying the longitudinal and lateral forces, the researchers determined the emission characteristics under different operating conditions and also evaluated the particle size distribution.

Internal drum test bench at the Institute of Vehicle System Technology of the Karlsruhe Institute of Technology (KIT)

The Palas® Promo® 2000 aerosol spectrometer and the welas® 2500 sensors, among others, played a crucial role in this study. The system is capable of continuously monitoring the particle mass concentration (PMC), particle number concentration (PNC) and particle size distribution of particulate matter. Its high measurement frequency and accuracy allowed researchers to capture changes in particulate emissions under different operating conditions, and its continuous real-time monitoring made the results more accurate and reliable.

The researchers found that two factors, longitudinal and lateral forces, had a significant effect on particulate emissions from tire pavements. Emission levels increased with increasing load, and the various tire types showed different emission characteristics. The results of the study show that there are significant differences in the emission behaviour of tires in different seasons (summer, winter and all-season). Winter tires have significantly higher emissions than summer tires, while all-season tires fall in between. In addition, ambient temperature also has an impact on emissions, with summer tires emitting less at lower temperatures and winter tires emitting less at higher temperatures.

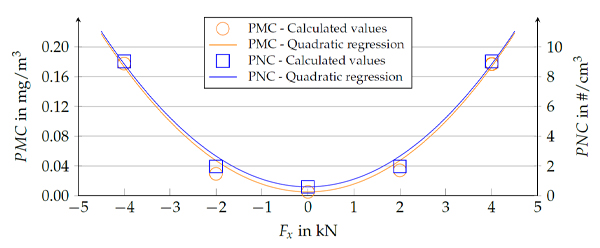

The Palas® Promo® 2000 aerosol spectrometer is capable of measuring particles in four measurement ranges from 0.2 µm to 100 µm, with a sampling frequency of up to 1 Hz, and is calibrated for each range using a special calibration dust (Palas® MonoDust). With an aerosol flow rate of 5 L/min, the device is capable of detecting particle count concentrations of up to 4 x 103 #/cm3 without any overlap errors, ensuring that experimental tests run smoothly and driving breakthroughs in research. For example, in the figure below, the Palas® aerosol spectrometer respectively presents calculated curves of particle concentration versus longitudinal and lateral forces for a summer tire at an ambient temperature of 25°C and an SRT value of 60.

Calculated courses of particle concentrations versus longitudinal force for the summer tire at an ambient temperature of 25 °C and at an SRT value of 60.

Calculated courses of particle concentrations versus lateral force for the summer tire at an ambient temperature of 25 °C and at an SRT value of 60.

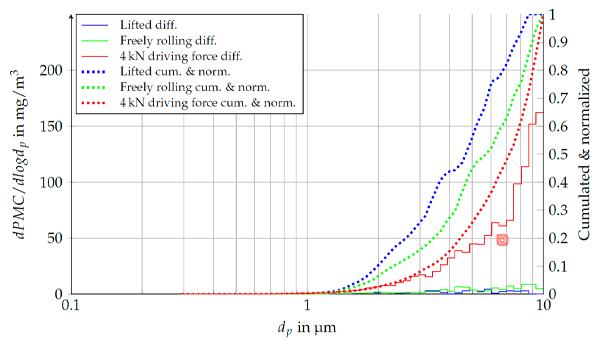

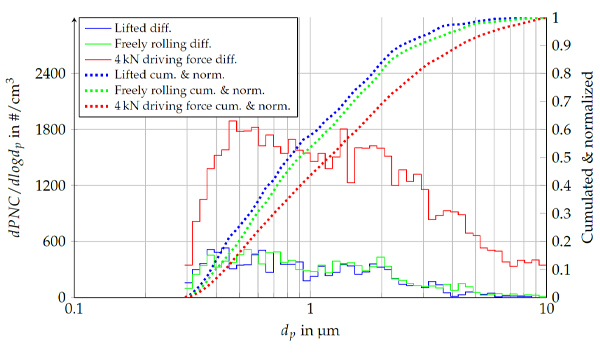

This study also looked at the particle size distribution of the particulate matter and found that the change in particle size under different load conditions was positively correlated with the load level. This means that under load conditions, the particle size becomes larger, which further affects the emission characteristics of the particulate matter. In addition to the Particle Mass Concentration (PMC) and Particle Number Concentration (PNC), the Palas® Promo® aerosol spectrometer records the particle size distribution of the particulate matter as it occurs each second. Its ability to record a scattered light pulse for each particle that passes through the measuring chamber, which ultimately leads to the size and mass of the particles based on the size of the scattered light pulse and other relevant parameters, were all important advantages that led to the selection of Palas® by the Institute of Vehicle System Technology of the Karlsruhe Institute of Technology. For example, the following graphs respectively show the distribution of typical particle masses and particle numbers for summer tires under different load conditions.

Typical particle mass distributions for different load conditions of a summer tire.

Typical particle number distributions for different load conditions of a summer tire.

Through this study, the researchers not only gained insight into the mechanisms of tire pavement particulate emissions, but also provided valuable guidance on how to reduce these emissions. In the future, these findings may help to formulate more scientifically sound transportation and environmental policies to improve air quality and safeguard people’s health. The application of the Palas® Promo® scattered-light aerosol spectrometer system also provides a powerful technical support for similar studies, which is expected to play an important role in more fields to promote environmental protection and sustainable development.

If you are interested in the technical article “Influence of Load Condition, Tire Type, and Ambient Temperature on the Emission of Tire–Road Particulate Matter”, please click to register to download the file in pdf format.

Palas® Promo® 2000 Aerosol Spectrometer

Advantages

· Measuring range of 0.2 to 100 µm (4 measuring ranges selectable in one device)

· Up to four measuring ranges in only one device:

‒ 0.2 µm ‒ 10 µm

‒ 0.3 µm ‒ 17 µm

‒ 0.6 µm ‒ 40 µm

‒ 2 µm ‒ 100 µm(additionally for sensors 2300 and 2500)

· Up to 128 size channels per measuring range

· Concentration range of 1 particle/cm3 to 106 particles/cm3

· Calibration curves for different refractive indices

· Very high and reproducible counting efficiency rate starting at 0.2 µm

· Pressure-resistant up to 10 bar (optional)

· Heatable to 250 °C (optional)

· Optical fiber technology

· Simple operation with a large touch display

· Calibration, cleaning and lamp replacement can all be performed independently by the customer

· External control by RS 232 or Ethernet

· With analysis software PDAnalyze

· Optional: Software PDControl for operation as welas® digital available

· Low maintenance

· Reliable function

· Reduces your operating expenses

Application

· Emission monitoring of installations

· Control of grinding and classification processes

· Monitoring of production processes in the food, pharmaceuticals and chemicals industries

· Testing of complete filters, inertial and wet separators or electrostatic precipitators

Palas® organizes a series of webinars on various topics to share professional knowledge of aerosol measurement technology. Palas® technical experts and industry scholars from all over the world will give you detailed online explanations. Welcome to register to attend and learn more about the webinars as soon as possible!

Topic: Characterization and monitoring of submicron & micron aerosols

When: Friday, September 22, 2023 15: 00 – 16: 00

Speaker: Mr. Yi Fangjie

Market Manager Industry and Science at Palas® China