The outbreak of the highly infectious variant of the COVID-19 virus Delta, is spreading worldwide. There has already been a number of confirmed cases in various regions in the country. The pandemic is far from over. For the public, wearing a mask remains a simple and effective measure to protect oneself. For mask manufacturers, the qualification rate of their products needs to be enhanced in order to provide safe products for the fight against COVID-19.

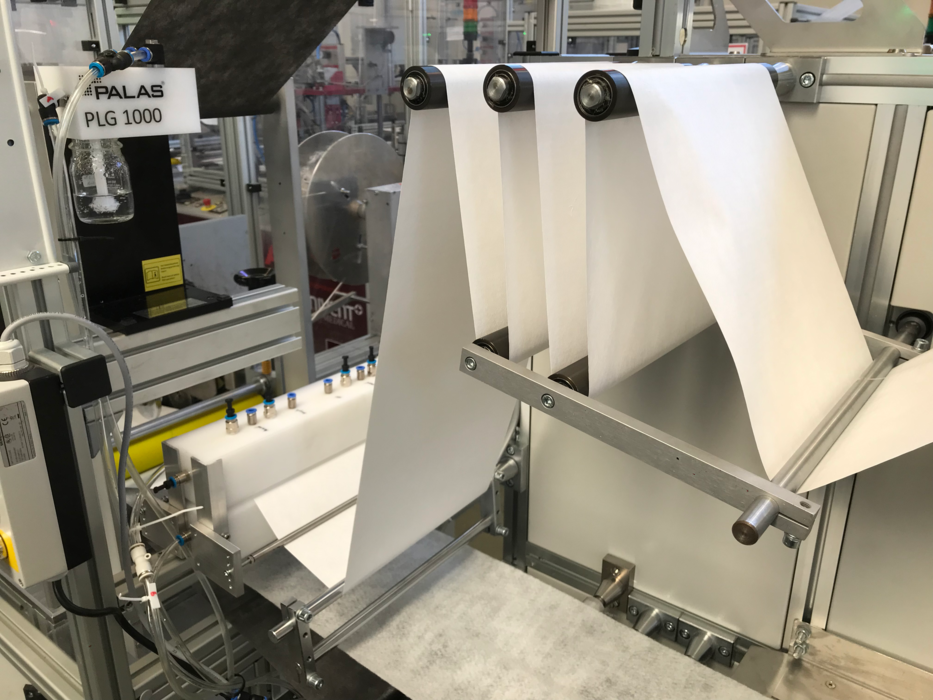

The Palas® P-MFP inline filter test stand is installed directly in the production line. This means that not only individual random samples of the final results are checked, but a continuous quality monitoring is possible throughout the entire production process. UNIVENT, a German mask manufacturer, has chosen this series of test stands to conduct quality inspections on the masks produced.

Palas® Filter Test System Checks Every Single Mask

Previously, UNIVENT also checked the filter material before the masks were produced, and conducted random tests to ensure the quality. Now, the Palas® P-MFP system for respiratory mask testing stand is installed on the production line of UNIVENT, checking every millimeter of the filter material in-line. Once there is a deviation, an automatic alarm will be set off by the test stand, which greatly improves the quality and efficiency of filter material testing. As UNIVENT Managing Director Thomas Vosseler said, this allows the company to guarantee the correct filter performance for each individual mask. Simultaneously, inferior filter material can be detected and rejected directly, resulting in fewer rejects and faulty production. This saves time and money.

Precise Measurement Technology

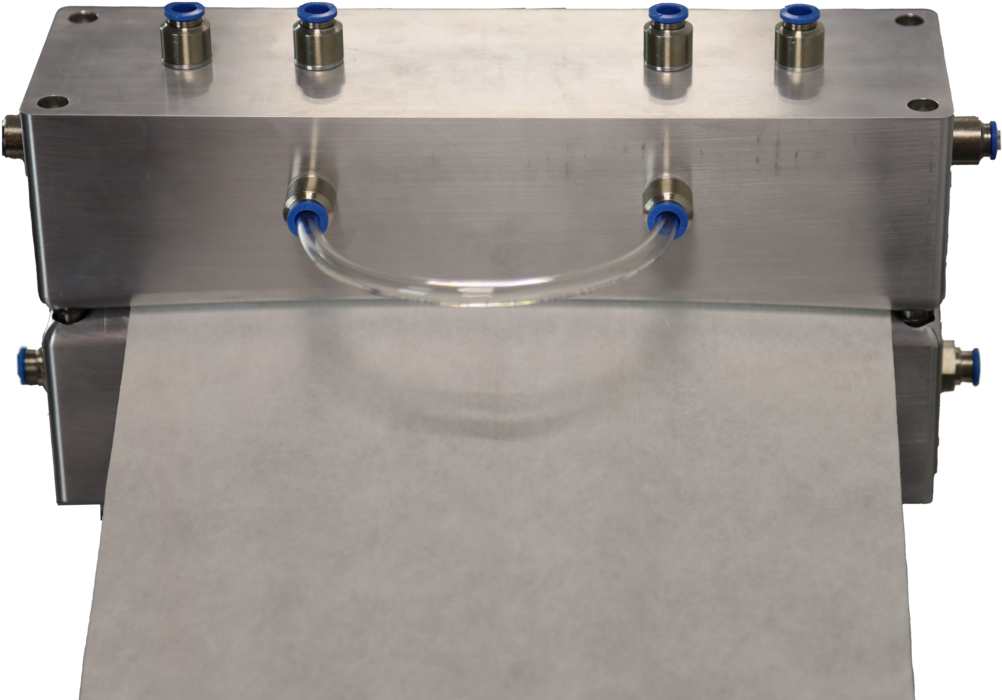

The quality of the mask is critical, because it is related to its ability to block airborne aerosols with viruses, especially small particle aerosols that are hard to be tested. As a specialist in filter material testing, Palas® has accumulated a wealth of experience in this field. The P-MFP system for respiratory mask testing stand uses the highly precise and proven Palas® technology. It is integrated directly into the production line to continuously monitor the differential pressure and filter mask efficiency in production facilities of mask and filter material in-line. The P-MFP system works with a medical-grade salt aerosol and low mass concentration to ensure that it will not have any impact on the initial filtration efficiency of the final product. Based on the Promo® LED 2,300 aerosol spectrometer, penetration is measured for the smallest particles in the virus-relevant range. This meets the hygienic requirements for the production of medical protective masks (FFP2).

Palas® has a long history of precise testing of filter materials, and this is the reason why it is trusted by professional mask manufacturing companies. Especially in the midst of the pandemic, Palas® is doing its best to help ensuring the safety of medical personnel and providing them with quality and reliable protective equipment.

Palas® P-MFP inline filter test stand

Benefits:

· Continuous quality statement

· Reduction of rejects

· Improvement of production efficiency

· Increase of internal cost efficiency

· Quality improvement and increased safety of the final product

· Future-proof: works with any type of aerosol without adjustments

· Easy to integrate into existing equipment

· Low maintenance

Applications:

· Inspection of filter material (melt blown) directly in the production line

· Quality assurance in mask production

· Continuous display of defects

Promo® LED 2300 Aerosol Spectrometer for Particle

Benefits:

· Self-explanatory operation

· Quick and highly resolved measurement of particle size distribution

· Long lifetime on lamp due to new LED-Technology

· Large measurement range from 145 nm up to 100 µm

· Photometer mode for measurements according to DIN EN 13274-7

Applications:

· Process monitoring of particle size and concentration

· Measurement of penetration of face masks (PMFT 1000 M)

· Measurement of fractional efficiency of particle size