Description

Many applications in research, development, and quality assurance require solid particle aerosols from powders and dusts.

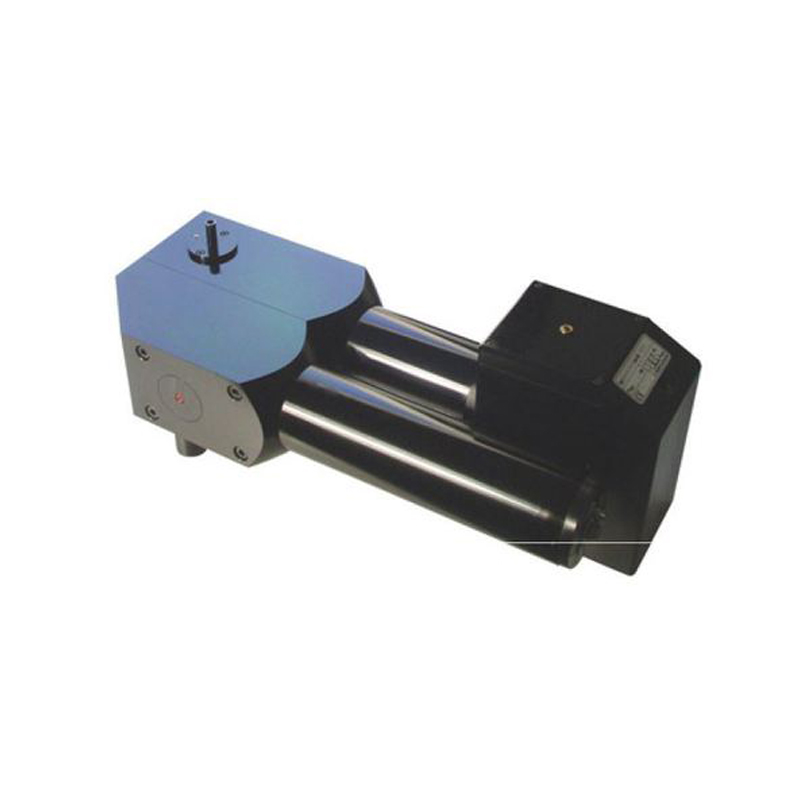

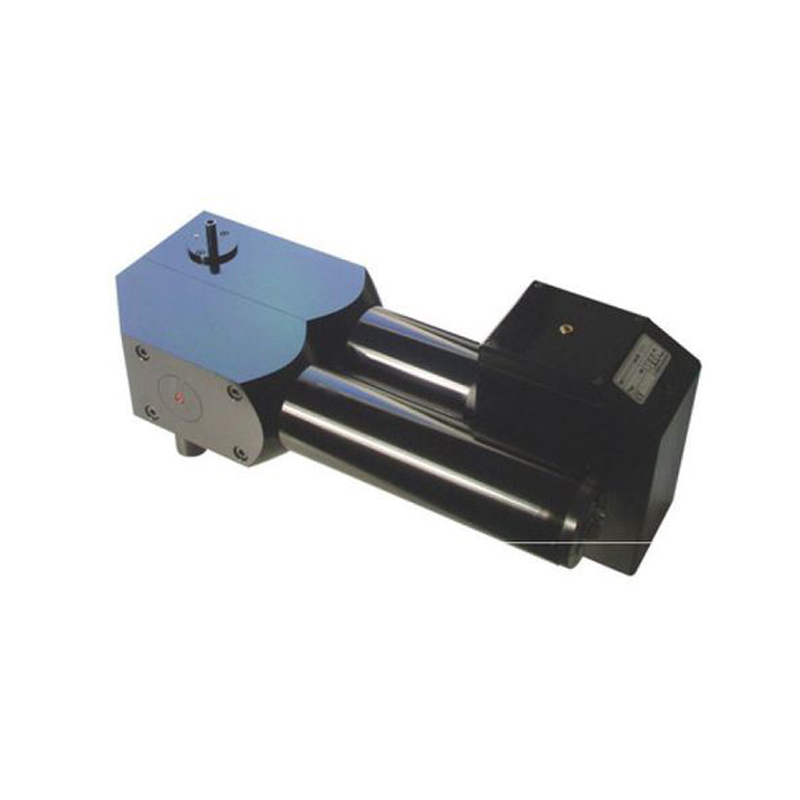

For over 20 years, the BEG 1000 has been successfully used for the reliable dispersion of non-cohesive powders, e.g. to generate test dusts, and flame soot within the size range of < 100 nm – 200 µm. The special advantage of this dispersion system is the fact that it is able to be used continuously with high dosing constancy for low mass flows of up to 8 g/h with the BEG 1000 A and for high mass flows of up to 6 kg/h with the BEG 1000 B. The special built-in components in the reservoir, the smooth conveyor belt, and the special ejector dispersion nozzle enable the BEG 1000 to provide a finely dispersed aerosol with optimal dosing constancy.

Function

The powder to be dispersed is simply poured into the reservoir (see Fig. 1). A stirrer at the bottom of the reservoir ensures uniform loading of the conveyor belt. A rabble arm and various built-in components in the reservoir prevent bridging in the reservoir.

Fig. 1: Principle of operation of the BEG 1000/BEG 2000

Dosing

The desired mass flows are able to be continuously and reproducibly adjusted with a controlled drive on the conveyor belt The even, smooth conveyor belt, the built-in components in the reservoir, and the precise drive on the conveyor belt ensure excellent dosing constancy.

Pulsed operation

The system can be operated in “powder”/”no powder” pulse mode with the “Stop” and “Belt” control keys and an electric timer switch in cycles of up to 5 sec, depending on the mass flow.

Dispersing

The ejector nozzles we developed provide excellent dispersion for various volume flows.