Description

With automatic mass flow control

The dosing unit on the BEG 2000 is continuously weighed for automatic mass flow control. The data from a touchscreen PC are continuously acquired and analyzed via a serial interface. As a result, the dispersed quantity of powder is always known and able to be automatically adjusted.

Dosing output on the BEG 2000 controlled using internal firmware

• Input of the mass flow in g/h

• Automatic mass flow control

• Recording of powder-specific calibration curves

• External control via PC or Modbus RTU

• Network-compatible

Function

The powder to be dispersed is simply poured into the reservoir (see Fig. 1). A stirrer at the bottom of the reservoir ensures uniform loading of the conveyor belt. A rabble arm and various built-in components in the reservoir prevent bridging in the reservoir.

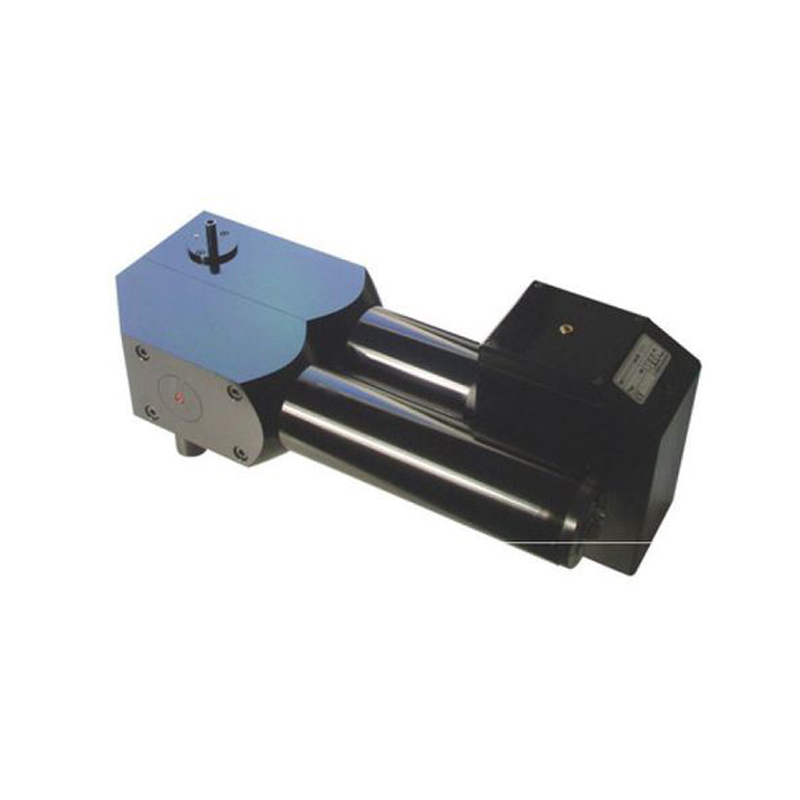

Fig. 1: Principle of operation of the BEG 1000/BEG 2000

Dosing

The desired mass flows are able to be continuously and reproducibly adjusted with a controlled drive on the conveyor belt The even, smooth conveyor belt, the built-in components in the reservoir, and the precise drive on the conveyor belt ensure excellent dosing constancy. Automatic readjustment is possible up to approx. 100 g/h.

Pulsed operation

The system can be operated in “powder”/”no powder” pulse mode with the “Stop” and “Belt” control keys and an electric timer switch in cycles of up to 5 sec, depending on the mass flow.

Dispersing

The ejector nozzles we developed provide excellent dispersion for various volume flows.