Description

With automatic mass flow control and automatic refill unit

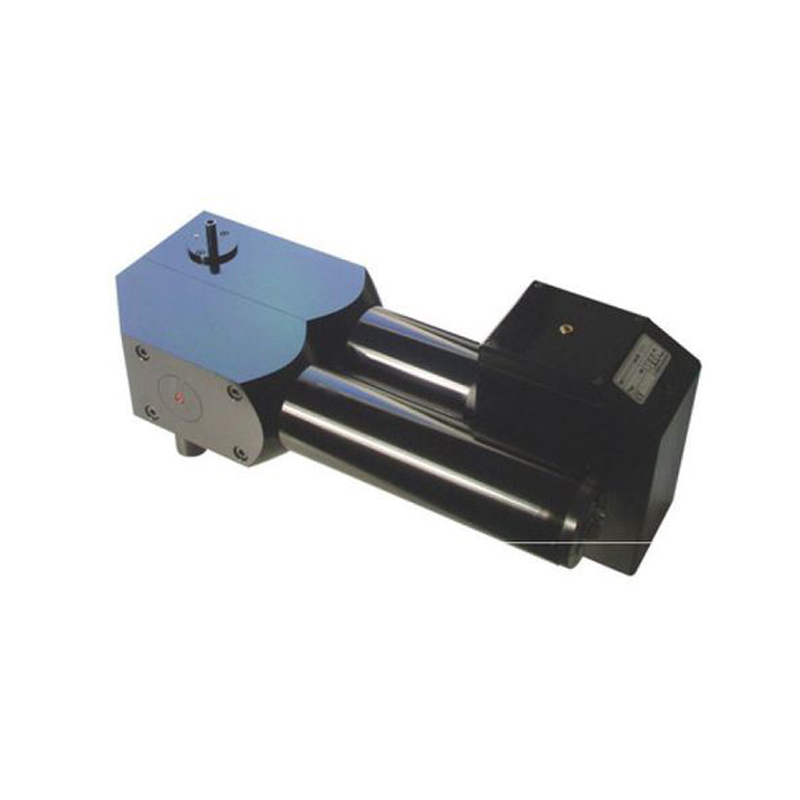

The refill system (see Figure) that was developed to automatically refill the BEG 3000 ensures uninterrupted dispersion over several days.

The dosing unit on the BEG 3000 is continuously weighed for automatic mass flow control. The data from a touchscreen PC are continuously acquired and analyzed via a serial interface. As a result, the dispersed quantity of powder is always known and able to be automatically adjusted.

Dosing output on the BEG 3000 controlled using internal firmware

• Input of the mass flow in g/h

• Automatic mass flow control

• Recording of powder-specific calibration curves

• External control via PC or Modbus RTU

• Network-compatible

Function

The powder to be dispersed is simply poured into the reservoir (see Fig. 1). A stirrer at the bottom of the reservoir ensures uniform loading of the conveyor belt. A rabble arm and various built-in components in the reservoir prevent bridging in the reservoir.

Fig. 1: Principle of operation of the BEG 1000/BEG 2000/BEG 3000

Dosing

The desired mass flows are able to be continuously and reproducibly adjusted with a controlled drive on the conveyor belt The even, smooth conveyor belt, the built-in components in the reservoir, and the precise drive on the conveyor belt ensure excellent dosing constancy.

Pulsed operation

The system can be operated in “powder”/”no powder” pulse mode with the “Stop” and “Belt” control keys and an electric timer switch in cycles of up to 5 sec, depending on the mass flow.

Dispersing

The ejector nozzles we developed provide excellent dispersion for various volume flows.