Description

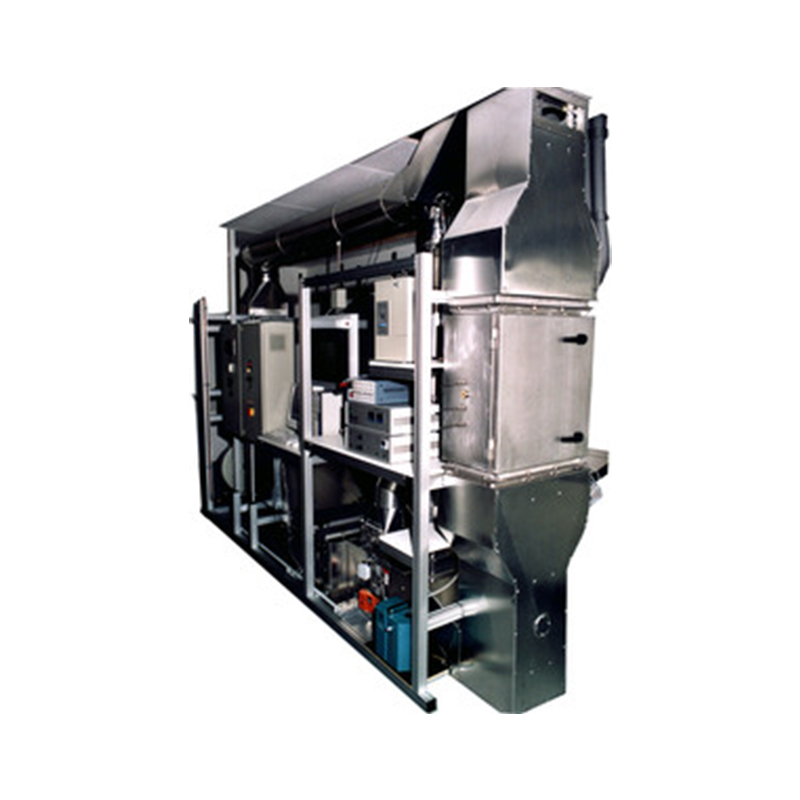

Palas® offers the CIF 1000 test rig with the Promo® 1000 unit for standard tests on motor vehicle passenger compartment filters in accordance with DIN 71460 part 1 and ISO/TS 11155-1.

The volume flow is automatically regulated and adjustable from 60 to 800 m3/h. With the aid of the CIF, both the fraction separation efficiency and the burden on the complete filters or filter media are measured and evaluated. Particle dosing for the filter test is performed with the brush generator RBG 1000, which has been internationally established for over 30 years. On the CIF 1000, overall and fraction separation efficiency are determined with the high-resolution light scattering spectrometer Promo® 1000. This allows reliable tests to determine the separation efficiency and burden tests to be performed across the entire measurement range for all particle sizes. The advantage of the Promo® 1000 is the larger measurement range for particles from 120 nm. Following ISO/TS 11155-1, the test rig is additionally equipped with the salt aerosol generator AGK 2000. In the testing conduit, filter media up to a size of approx. 220 x 500 mm can also be tested under the conditions stated above. In order to test the influence of real ambient conditions on the separation behavior of filters, Palas®offers an upgrade to the CIF test rig with climate technology components foradjustment of the temperature between +18°C and +90°C and the relative humidity between 30% and 70%. As an option, the test rig can be upgraded after provision of the measuring equipment for gas analysis for investigations of the adsorption and desorption dynamics following DIN 71460 part 2 and ISO/TS 11155 part 2.

Automation

The CIF is equipped with a high-pressure ventilator, which can be throttled on the pressure side with infinitely variable adjustment and is frequency-controlled, and which can be automatically regulated via the FTControl filter test software for regulation of the volume flow. Furthermore, sensor data such as the volume flow, temperature, relative humidity and differential pressure at the filter are also recorded automatically during the filter test. The aerosol generators and the corona discharge can be actuated via the FTControl software.

Measurement of the fraction separation efficiency

Fig 1: Example showing a comparison of fraction separation efficiencies

• Clear demonstration of the separation efficiency of your filters or filter media throughout the entire measurement range from 120 nm to 40 µm with the Promo® 1000 system

• Highest measurement reproducibility and repeatability highlight even fine differences in the separation efficiency

• Short measurement times of around 2 minutes per separation efficiency measurement thanks to optimized application

• Simple comparison of separation efficiency curves, calculation of mean values also possible

Burden / hold time measurement and record of the pressure loss curve

Fig 2: Example of the hold time measurement

• Performance of measurements of the fraction separation efficiency during dust application; pressure loss or measurement time can be pre-selected as the abort criterion

• Determination and representation of the pressure loss curve and retention curve in diagram and table form The representation of the particle diameters at 80% and 90% separation provides additional information.

• Comparison of the fraction separation efficiencies during the different loading steps

• Shortening of the measurement times, e.g. through increased aerosol concentration

Further component:

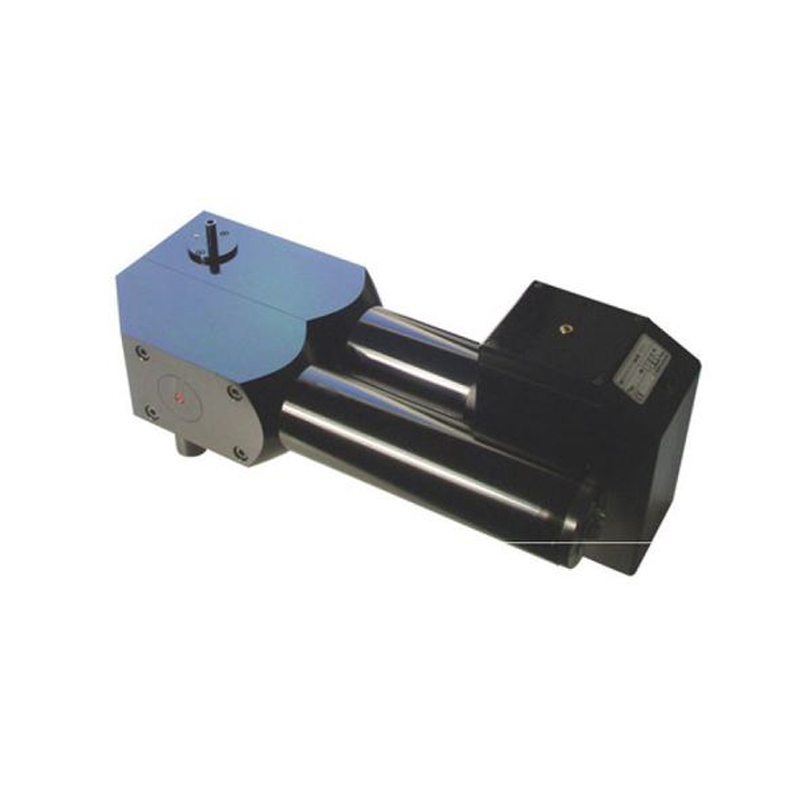

• Measurement point switching device