Description

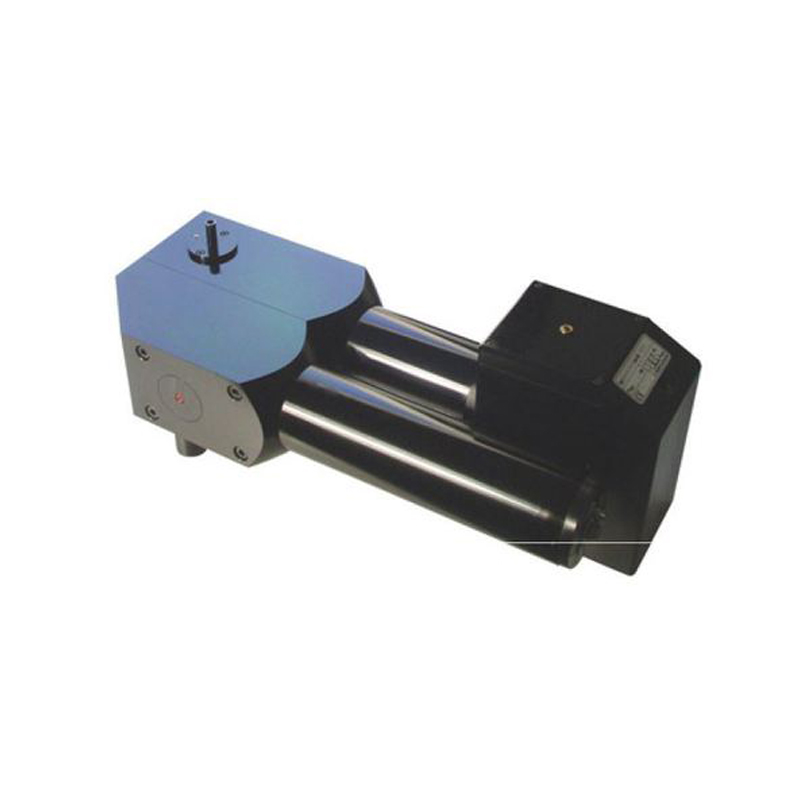

Fig. 1: DustView II

Dust is generated during the production, conveyance, and filling of powders, bulk materials, granulates, pellets, etc. This dust can have negative impacts on occupational safety and the reliability of production.

In addition, dust pollutes the environment and plays a not inconsiderable role in the loss of production.

The first essential step in the prevention of undesirable dust is to measure dust formation following free fall and impact.

The DustView II fully automated dust measurement system enables rapid and precise measurement of even the smallest fractions of dust generated following free fall and impact.

By means of the DustView II, the individual dust formation behavior can be determined quickly, clearly and reproducibly, so that the application of the system especially in the area of quality assurance of powders is outstandingly possible.

Principle of operation

Fig. 2: Schematic design of the DustView II

• Pour the sample (typically 30 g bulk material) into the sample funnel.

• Start of measurement: Valve opens automatically and sample falls into dust reservoir.

• Measurement begins immediately after the valve opens.

• The dust is dispersed in the reservoir. The resulting dust development causes an attenuation of the laser beam (extinction measurement). This attenuation is observed during measurement and classified as a dust value between 0 and 100 0 = No attenuation of the laser beam due to dust development, i.e. there are only minor dust fractions in the reservoir 100 = Complete attenuation of the laser beam due to dust development

• The dust values change over time and indicate the attenuation of the laser beam in relation to the 0 value (= no attenuation). The 0 value is automatically determined without dust prior to each measurement (calibration).

• End of measurement and automatic storage of the data

Determination of the dust number as a reference value for dust behavior

The dust number (STZ) consists of the maximum dust value and the dust value indicated 30 seconds after the maximum dust value has been reached:

Dust number (STZ) = Max. value + 30-s value

Measurement results (example)

Fig. 3: Comparison of two bulk materials

Due to its finer particle size distribution and the specific characteristics of the material, the cement sample clearly generates more dust than the wheat flour sample. Wheat flour contains considerably larger particles that quickly settle to the bottom of the reservoir, while nearly all of the finer cement particles remain suspended in the air even after 30 s.

These comparisons enable a product to be easily and verifiably optimized with respect to dust behavior.

The high reproducibility of these measurements enables easy and economical production controls of bulk materials.

Firmware and software

Following completion of the measurement, the results are displayed directly on the device and are shown as numerical values and in the form of a chronological sequence. Automatic storage of the results enables the analysis of earlier measurements without an additional PC.

The system provides the option to create reports as a PDF or text file. In addition, a report can be printed out immediately using a printer.

In addition to the analysis of individual measurements, the DustView II firmware also enables the comparison of up to ten different measurements. The report creation options mentioned above are also available here.

Multiple measurements can also be averaged easily and quickly using the series measurement option.

Evaluation software for the analysis of measurements on an external PC is also included.

The DustView II measurement device was developed during the AIF Pro INNO II Research project (KF 0295803WZ8) in cooperation with the Bergischen Universität Wuppertal, Prof.-Dr. E. Schmidt during the time 2008 and 2010.