Description

The Fidas® Fly 200 is a combination of an ultra-light real-time dust monitor made by Palas® and a flight robot made by Airclip Service GmbH & Co KG.

With the Fidas® Fly 200 as measuring system has been created, which enables – based on the well-approved measuring technique of the Fidas® systems – the continuous and simultaneous measurement of the PM-fractions PM1, PM2.5, PM4, PM10, TSP or respirable, thoracic, and inhalable mass fractions as per DIN EN 481 as well as in addition the particle number concentration as well as the particle size distribution in 32 size classes per decade within the particle size range of 0.18 – 18 μm or 0.5 – 40 μm – and all this in an additional spatial dimension.

This is made possible by applying the flight robot HORUS of the company Airclip GmbH, Dresden, Germany as a carrier unit for the ultra-light fine dust monitoring system Fidas® Fly 100.

The flight robot is an octocopter, offers an exceptionally high operational safety due to redundant layout of the flight system and can be controlled manually by hand as well as automatically. By using GPS, defined way-points / routes can be patrolled in an automatic and reproducible way.

The flight time per battery charge is approx. 20 min, the exchange of battery is only about 2 min.

The Fidas® Fly 200 allows among others fine dust measurements at up to now inaccessible locations (e.g. in the area of transfer of emissions to the athmosphere), can be used for the assessment especially of line and area sources (e.g. open mining sites) and also deliver valuable parameters for R&D purposes (e.g. for prognosis models).

The Fidas® Fly 200 uses the recognized measurement technology of optical light scattering of single particles and is equipped with an LED light source with high intensity (dpmin = 180 nm), highly stable output and long lifetime. The calibration of the system can be checked and adjusted, if necessary, easily and quickly also under field conditions on site at any time with the help of a monodisperse test powder.

The Fidas® Fly 200 is equipped with a data logger with 4 GB Compact Flash storage. The firmware supports complete remote access with remote maintenance and optional data storage at www.palas.de/user.

The Fidas® Fly 200 is distributed by the company Airclip GmbH, Dresden, Germany ( Contact Airclip ).

All necessary training / education for the operation of the flight robot are carried there out, too. Furthermore it can be agreed there on flight campaigns as a service (e.g. for project-related campaigns).

Measuring principle

The actual aerosol sensor is an optical aerosol spectrometer that determines the particle size using Lorenz‐Mie scattered light analysis of single particles. The single particles move through an optically differentiated measurement volume that is homogeneously illuminated with white light. Each particle generates a scattered light impulse that is detected at an angle of 85° to 95° degrees. The particle number is measured based on the number of scattered light impulses. The level of the scattered light impulse is a measure of the particle size diameter.

The lower detection limit for immission measurement was able to be reduced to 180 nm through improved optics, higher light density using a new white LED as the light source, and improved signal analysis (logarithmic analog digital converter). This enables greatly improved detection, especially of smaller particles, which are mainly found at high concentrations near roadsides (see Fig. 1).

Fig. 1: Higher sensitivity with the Fidas® fine dust measurement system for the 0.18 – 18 µm particle size range

The better the classification accuracy and the resolution capacity, the more accurate the definition of the particle size distribution.

Using a white light source enables a precise and unambiguous calibration curve to be obtained, resulting in an extremely high size resolution. The patented T-stop provides a precisely defined optical measurement volume and enables particle measurement without border-zone errors, resulting in a precise size measurement. The new digitized electronic signal analysis system enables the rapid identification and correction of coincidence, as necessary.

Fig. 2: Comparison of the algorithms for conversion of the particle size distribution by PM values

In order to convert the measured values into a mass or mass fraction, the high-resolution particle size distribution in each value is multiplied by a correlation factor that reflects the different sources (e.g. combustion aerosols, tire wear, pollen) of the environmental aerosol (see Fig. 2). A mass fraction is obtained by additionally applying the separation curve (see DIN EN 481) to the determined particle size distribution. Multiple separation curves can be used simultaneously for the same size distribution, which enables the simultaneous output of PM10, PM2.5, PM1 (and others). For example the Fidas® Fly 200 can be operated with the same conversion algorithm, which has also been implemented in the type-approved and certified ambient air monitoring system Fidas® 200 for regulatory monitoring of ambient PM2.5 and PM10 concentrations.

The delivered software allows for manifold evaluations and presentations of the measured data.

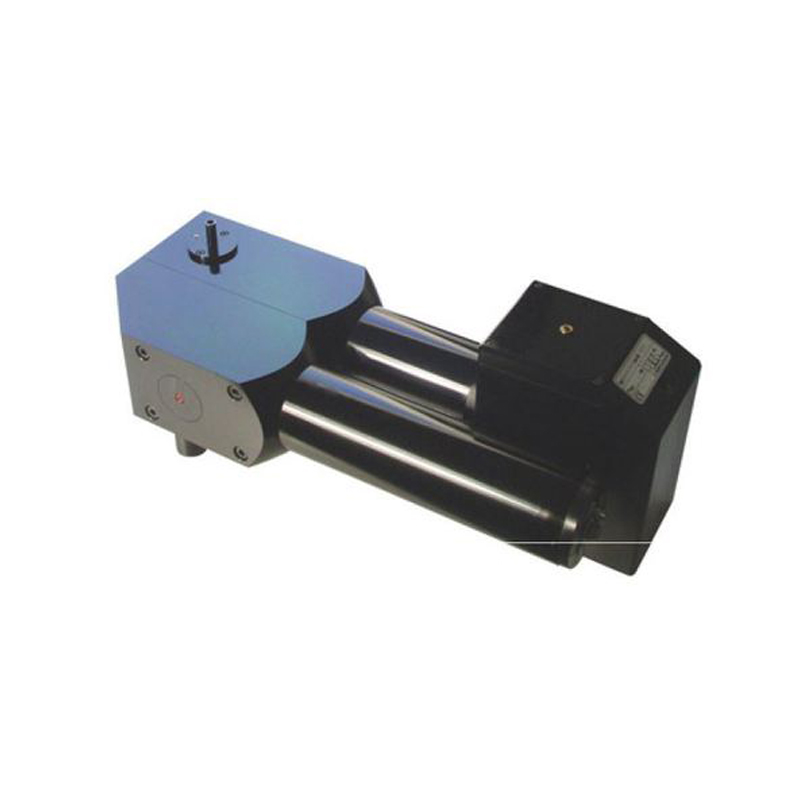

Fig. 3: Flight of Fidas® Fly 200