Description

Fidas® 200 E is an aerosol spectrometer developed specifically for regulatory air pollution control. It analyzes continuously the fine dust particles present in the ambient air in the size range 180 nm – 18 µm and calculates simultaneously the immission values PM10 and PM2.5 to be monitored by law. At the same time PM1, PM4, PMtot, the particle number concentration Cn and the particle size distribution are calculated and recorded. It thus delivers comprehensive information about the fine dust particles, as only provided by a counting, single particle measuring principle.

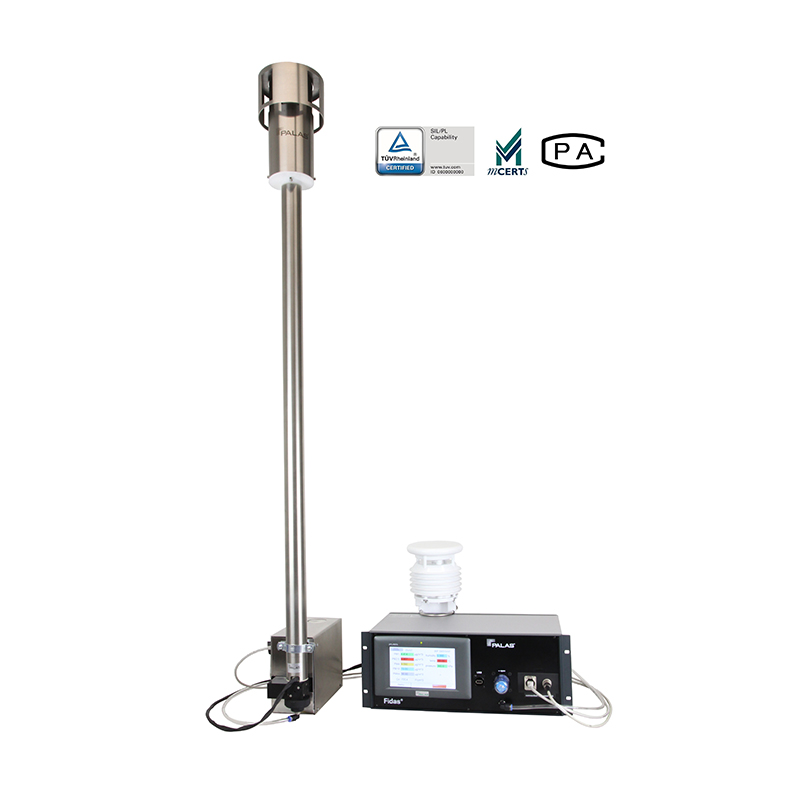

The version Fidas® 200 E displayed here consists of a 19″ rack mount device and a separate sensor (3 m connection distance, other lengths on request) designed for installation in air conditioned monitoring stations (temperature range 5 – 40 °C). The separate sensor, which locks to the lower end of the aerosol sampling tube, considerably facilitates installation in stations with existing ceiling glands. Variants of the Fidas® 200 E are the basic type Fidas 200® and the Fidas® 200 S designed for outdoor installation (including a stainless steel cabinet).

Fidas® 200 E as well as its functionally identical variations Fidas® 200 and Fidas® 200 S are currently the only optical single particle measuring devices that are type approved for simultaneous monitoring of PM10 and PM2.5 according to standards VDI 4202-1, VDI 4203-3, EN 12341, EN 14907, EN 16450, and the EU Equivalence Guide GDE and certified in compliance with standards EN 15267-1 and -2. Type approval declaration of the Fidas® 200 E was published first in the German Federal Gazette BAnz AT 14th March 2016 B7 in chapter V, notification 6. The certificate of product conformity according to EN 15267 issued by TÜV Rheinland and the German Federal Environmental Agency (version Fidas® 200 E listed on p. 4), as well as the measuring system test report for the version Fidas® 200 S compiled by TÜV Rheinland are published at www.qal1.eu .

Fig. 1: EN 15267 certificate, page 4 for Fidas® 200 E

Beyond that Fidas® 200 as well as Fidas® 200 E and Fidas® 200 S are also type approved and certified in the UK (Defra Approval) in compliance with the requirements of “MCERTS Performance Standards for CAMS” and “MCERTS for UK Particulate Matter”. The respective MCERTS/DEFRA Approval certificate as well as the test report are publicly available.

Fig. 2: MCERTS/DEFRA Approval for Fidas® 200

Fidas® 200 E utilizes the acknowledged principle of single particle light scattering size analysis and is equipped with an LED light source of high intensity (dp,min = 180 nm), highly stable light output and long lifetime. The calibration of the instrument can be verified and, if necessary, adjusted easily and quickly at any time even when installed on site, using a monodisperse test aerosol.

The sampling system of the Fidas® 200 E operates with a volume flow of approximately 0.3 m3/h. It is equipped with a Sigma-2 sampling head according to VDI 2119-4, which allows representative sampling even under strong wind conditions, and a drying line which prevents condensation from causing measurement errors. The drying line (Intelligent Aerosol Drying System – IADS) is controlled based on ambient air temperature, pressure, and relative humidity. These data are provided by a weather station; optionally wind velocity, wind direction, and precipitation data can be provided as well. A filter holder for circular plane filters (47 mm dia.) is integrated into the sampling system, which allows, e. g., subsequent chemical analysis of the aerosol composition.

Fidas® 200 E offers numerous communications options and allows full remote control and maintenance of the system as well as online data access via palas.de . The software provided along with the system offers versatile options for evaluation (e. g., comprehensive statistics and averaging) and export of measurement data.

The actual aerosol sensor is an optical aerosol spectrometer that determines the particle size using Lorenz‐Mie scattered light analysis of single particles. The single particles move through an optically differentiated measurement volume that is homogeneously illuminated with white light. Each particle generates a scattered light impulse that is detected at an angle of 85° to 95° degrees. The particle number is measured based on the number of scattered light impulses. The level of the scattered light impulse is a measure of the particle size diameter.

Precise optics, high light output from the polychromatic LED used, and powerful signal processing electronics using logarithmic A/D conversion allow detection of particles down to 180 nm diameter. The detection of small particles, which can be found in high concentration in particular close to roads, is of importance, e. g., for the correct determination of PM2.5. The influence of the lower particle size detection limit is illustrated in Fig. 3 in comparison with a system which has a lower detection limit of 300 nm.

Fig. 2: MCERTS/DEFRA Approval for Fidas® 200

Fidas® 200 E utilizes the acknowledged principle of single particle light scattering size analysis and is equipped with an LED light source of high intensity (dp,min = 180 nm), highly stable light output and long lifetime. The calibration of the instrument can be verified and, if necessary, adjusted easily and quickly at any time even when installed on site, using a monodisperse test aerosol.

The sampling system of the Fidas® 200 E operates with a volume flow of approximately 0.3 m3/h. It is equipped with a Sigma-2 sampling head according to VDI 2119-4, which allows representative sampling even under strong wind conditions, and a drying line which prevents condensation from causing measurement errors. The drying line (Intelligent Aerosol Drying System – IADS) is controlled based on ambient air temperature, pressure, and relative humidity. These data are provided by a weather station; optionally wind velocity, wind direction, and precipitation data can be provided as well. A filter holder for circular plane filters (47 mm dia.) is integrated into the sampling system, which allows, e. g., subsequent chemical analysis of the aerosol composition.

Fidas® 200 E offers numerous communications options and allows full remote control and maintenance of the system as well as online data access via palas.de . The software provided along with the system offers versatile options for evaluation (e. g., comprehensive statistics and averaging) and export of measurement data.

The actual aerosol sensor is an optical aerosol spectrometer that determines the particle size using Lorenz‐Mie scattered light analysis of single particles. The single particles move through an optically differentiated measurement volume that is homogeneously illuminated with white light. Each particle generates a scattered light impulse that is detected at an angle of 85° to 95° degrees. The particle number is measured based on the number of scattered light impulses. The level of the scattered light impulse is a measure of the particle size diameter.

Precise optics, high light output from the polychromatic LED used, and powerful signal processing electronics using logarithmic A/D conversion allow detection of particles down to 180 nm diameter. The detection of small particles, which can be found in high concentration in particular close to roads, is of importance, e. g., for the correct determination of PM2.5. The influence of the lower particle size detection limit is illustrated in Fig. 3 in comparison with a system which has a lower detection limit of 300 nm.

Fig. 3: Higher sensitivity with the Fidas® fine dust measurement system in the size range 0.18 – 18 µm

The better the classification precision and the resolution of a particle sizing instrument, the more accurately the particle size distribution can be determined. The Fidas® 200 E light source allows for an unambiguous calibration curve, and thus very high particle size resolution, resp., accuracy of classification. The measurement volume of the Fidas® sensor is precisely optically delimited using the patented T-aperture technique, which allows particle sizing without border zone errors and so contributes to sizing accuracy. Powerful digital signal processing makes it possible to identify and, if required, compensate coincident readings (caused by concurrent presence of multiple particles).

Fig. 4: Comparison of algorithms for converting particle size distribution data to PM values

For calculating mass or a mass fraction from measured data the particle size distribution is processed with a (yet particle size dependent) conversion factor (see Fig. 4). This takes into account that, depending on particle size, ambient aerosol is composed of particles from different sources (such as combustion aerosols, tire attrition, pollen). A mass fraction like, e. g., PM10, is finally determined by applying the associated separation curve (see EN 481) to the particle size distribution data. Even though the optical measuring technique determines particle mass indirectly (equivalence method), which means that exact identity with gravimetric results is not guranteed in each and any case, the empirical knowledge used in processing the measured data ensures a very good correlation with the standard reference method (see Fig. 5), as shown during type approval testing.

Fig. 5: PM10 reference equivalence function of the Fidas® 200 S in comparison with a reference small-filter device during the course of suitability testing from the “Report on supplementary testing of the Fidas®200 S respectively Fidas®200 measuring system manufactured by Palas® GmbH for the components suspended particulate matter PM10 and PM2.5, TÜV report no.: 936/21227195/B”.

Multiple separation curves can be applied simultaneously to the same size distribution data which allows simultaneous calculation and output of, e. g., PM10 and PM2.5 and other mass fractions.