Description

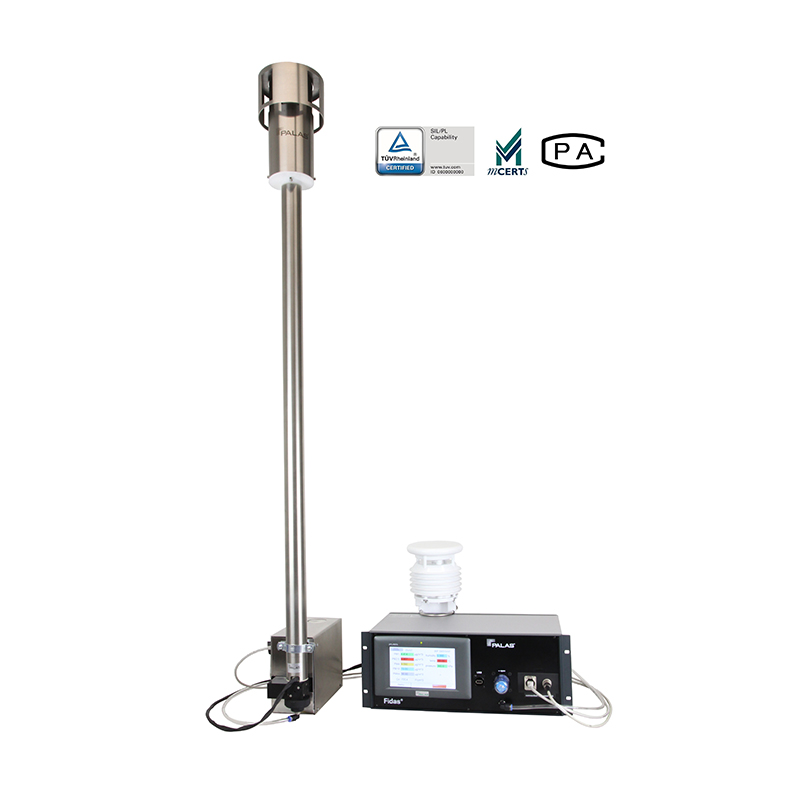

Fig. 1: MFP 1000 HEPA

The MFP filter test rig is a modular filter testing system for flat filter media and small mini-filters. Pressure loss curves, fraction separation efficiency or burden can be determined within a very short period of time – both reliably and cost-effectively.

With the aid of the new light scattering spectrometer Promo® 1000, clear and reliable determination of the aerosol concentration and the particle size can be ensured, and therefore a clear determination of the fraction separation efficiency and the MPPS range for HEPA filters.

Alternatively, other aerosol spectrometers can also be used for the filter tests.

Thanks to the movable dilution cascades, the test rig can be changed over from salt aerosols to DEHS aerosols within a very short space of time, with no need for cleaning.

The largely automated setup of the test sequence together with the clearly defined individual components and the individually adjustable sequence programs of the filter test software FTControl combine to deliver the high reliability of our measurement results.

Our quality in detail

Fig. 2: MFP 1000 HEPA

1. Variable aerosol generation through the use of special dispersers for KCl/NaCl or DEHS. Integrated drying length, no silica gel! The generated salt aerosol is dried using dry compressed air. The volume flow for drying can be individually regulated via mass flow controllers.

2. Corona discharge (optional): Adjustable ion stream for different mass flows. Adjustable mixed air for inflow speeds from 1.5 to 40 cm/s. Monitoring and control are implemented via mass flow controllers.

3. Mobile pneumatic filter holder for fast removal and loading of the test rig.

4. Movable dilution cascades: The dilution cascades enable defined dilution of the applied test aerosol by the factors 10, 100, 1,000 and 10,000. As they are movable, the test rig can be changed over in a very short time from salt aerosols to DEHS aerosol. Lengthy or complex cleaning of the systems is not required.

5. Light scattering spectrometer Promo® 1000 for HEPA filters: The Palas® filter test software FTControl controls the light scattering spectrometer that is used and evaluates the data. Palas® recommends the following for clear measurement of the fraction separation efficiency and determination of the MPPS range:

• Light scattering spectrometer Promo® 1000 for HEPA filters

• Light scattering spectrometer with lower detection limit from 90nm for HEPA / ULPA filters

Measurement of fraction separation efficiency, MPPS determination

Fig. 3: Promo® 1000: Fraction separation efficiency / MPPS at 130 nm, Promo® 1000

Fig. 4: Model 3340: Comparison of fraction separation efficiencies, MPPS at 120 nm

• Clear demonstration of the separation efficiency of your filter medium throughout the entire measurement range

• Clear determination of the MPPS range

• With its maximum sensitivity, the particle measurement technology can highlight even fine differences in separation efficiency.

• Short measurement times of around 2 minutes per separation efficiency measurement thanks to optimized aerosol application

• Simple comparison of separation efficiency curves, calculation of mean values also possible

Automation

The MFP 1000 HEPA has an integrated mass flow controller that it uses to control the volume flow; this can be automatically monitored and controlled via the FTControl filter test software. The sensor data such as the volume flow and differential pressure at the filter are automatically also recorded during the filter test.

Burden / hold time measurement and record of the pressure loss curve

Fig. 5: Example: Hold time measurement

• Performance of measurements of the fraction separation efficiency during dust application; pressure loss or measurement time can be pre-selected as the abort criterion

• Determination and representation of the pressure loss curve and retention curve in diagram and table form The representation of the particle diameters at 80% and 95 % separation efficiency provides additional information.

• Comparison of the fraction separation efficiencies during the different burdening steps

• Shortening of the measurement times, e.g. through increased dust concentration