Description

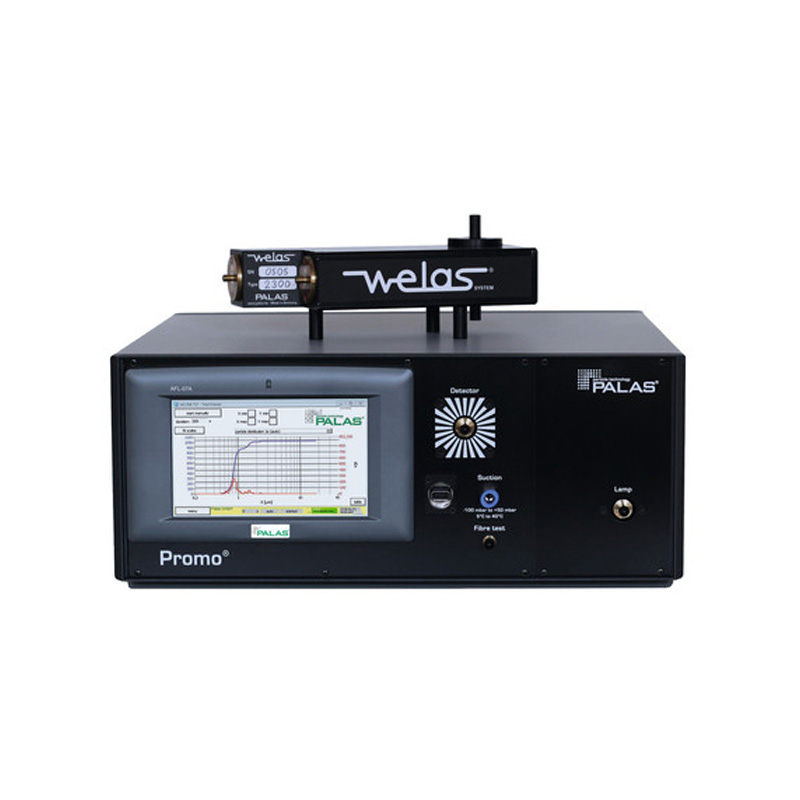

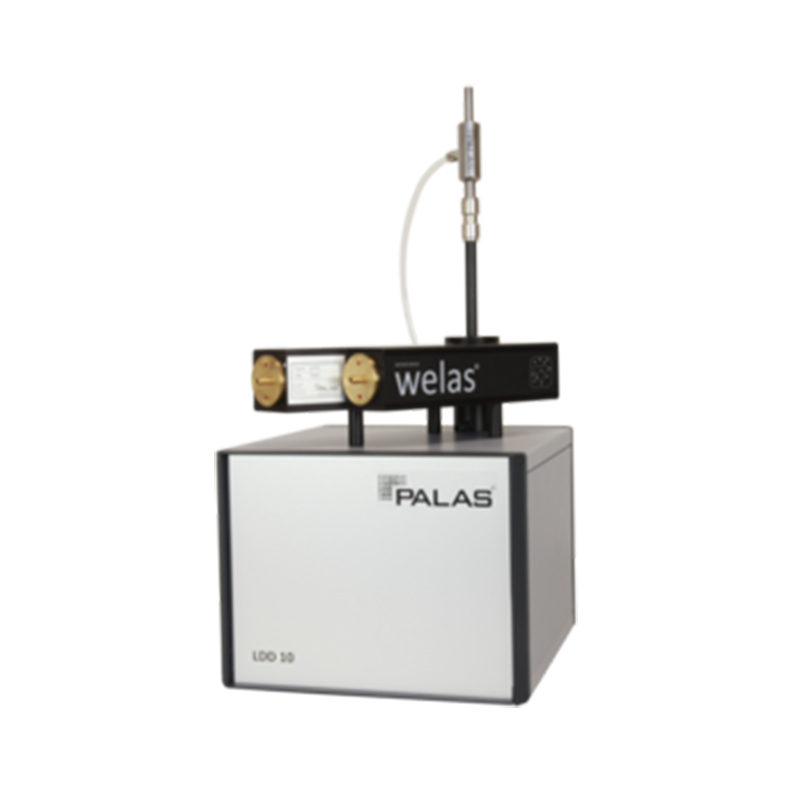

Promo® 2000 is a light-scattering aerosol spectrometer system for particle size analysis and concentration determination that can be equipped with all welas® sensors.

On Promo® 2000, the welas® sensors equipped with different measurement volumes, as required, can be easily connected via fiber optic cables and interchanged as required. These sensors allow reliable measurement in the concentration range from < 1 particle/cm3 up to 106 particles/cm3 in gases. Please observe the “welas® sensors” product data sheet.

Unique are up to four measuring ranges in only one device:

• 0.2 µm – 10 µm

• 0.3 µm – 17 µm

• 0.6 µm – 40 µm

• 2 µm – 100 µm (additionally for sensors 2300 and 2500).

Promo® 2000 is famous for up to 128 size channels per measuring range and a concentration range from < 1 particle/cm3 to 106 particles/cm3.

A touch display ensures user-friendly operation. Measurements can be started easily, and all data, such as the current number distribution and the number concentration, as well as 24 further statistical values, can be evaluated and displayed in real time.

With Promo® as a standalone measuring device (i.e. without external computer) measurements are performed continuously. All incoming data can be stored with a maximum temporal resolution of 1 s. Promo® 2000 can therefore measure and save data over weeks independently. For data transfer, Promo® can also be integrated into a company network.

Promo® 2000 has a standard interface and can be controlled by a process control system or by a simple Labview program. For this reason, Promo® 2000 is especially well suited for control and monitoring applications. Temperature, humidity and pressure sensors can be connected.

Palas® offers remote maintenance for the device and data access via www.palas.de/user.

The new Promo® 2000 measurement technology:

Promo® 2000 offers a new, fast 20 MHz signal processing processor, which analyses the progression of each particle signal. This makes it possible to recognise coincidental events in light scattering measurement technology at the individual signal and correct them (according to Dr. Umhauer / Prof. Dr. Sachweh). This way it is possible to increase the maximum concentration limit up to 106 particles/cm3 (welas® 2070 sensor). Also in low concentrations < 1 particle/cm3 with the welas® 2500 sensor, this leads to a higher measuring accuracy.

High classification accuracy and high particle size resolution are guaranteed by the following special features (see Graph 1):

• White light and 90° light-scattering detection

⇒ Unambiguous calibration curve

• Patented T-aperture

⇒ No border zone error

• New digital individual signal processing

⇒ Coincidence detection and correction of the individual signal making it possible to measure higher concentrations

Graph 1: Example with 2200 sensor

Promo® 2000 is characterized by its very high counting efficiency starting from 0.2 µm!

Graph 2: Example with 2200 sensor, in relation to LAS-X II

The new Promo® 2000:

The Promo® 2000 is characterized by its optical fibre technology. The welas® aerosol sensor is connected via a fiber optic cable with a length up to 30 m with the Promo control unit. This leads to a minimization of particle losses in long sampling lines by simply installing the sensor directly at the sampling location.