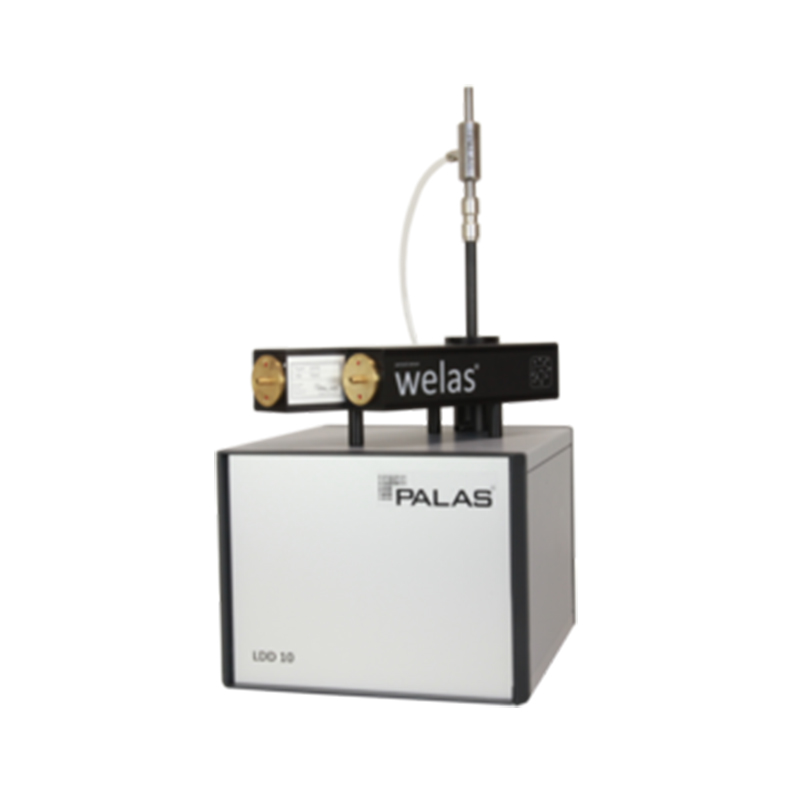

Description

This dispersion system is able to continuously generate low mass flows, e.g. 8 g/h, with optimal dosing constancy and control with automatic mass flow monitoring. The automatic refill unit and the weighing unit enable this dispersion system to be successfully used for continuous dosing over several days. Mass flow setting of approx. 100 g/h – 6 kg/h based on SAE fine, A2 dust