Description

Version MFP 3000 M is especially tailored to the requirements of the ISO 5011 and ISO TS 19713-2 measurement procedures:

Aerosol generation with RBG 1000 G:

The dosing air for the RBG 1000 G solid particle aerosol generator is regulated with a mass flow controller. This ensures the same operating conditions are always maintained.

Additional solid material reservoirs and dispersing covers offer an optimal dosing time at different air volume flows.

DLB 2000 compressed air humidifier for the dispersion air:

Dry compressed air is normally used for aerosol generation, whereby, at the very low volume flows in filter media testing, the rel. humidity of the test volume flow can drop considerably. The DLB 2000 compressed air humidifier can condition the rel. humidity and temperature of the RBG 1000 dispersion air precisely to the required values and thus minimises the influence of rel. humidity on the dust holding capacity to be measured.

Aerosol inlet on MFP 3000 M:

The aerosol inlet on the MFP 3000 M is especially tailored to the high mass concentration of 1000 mg/m³ and ensures a homogeneous distribution of the test aerosol in the raw gas channel. The simple construction allows the raw gas channel to be easily cleaned.

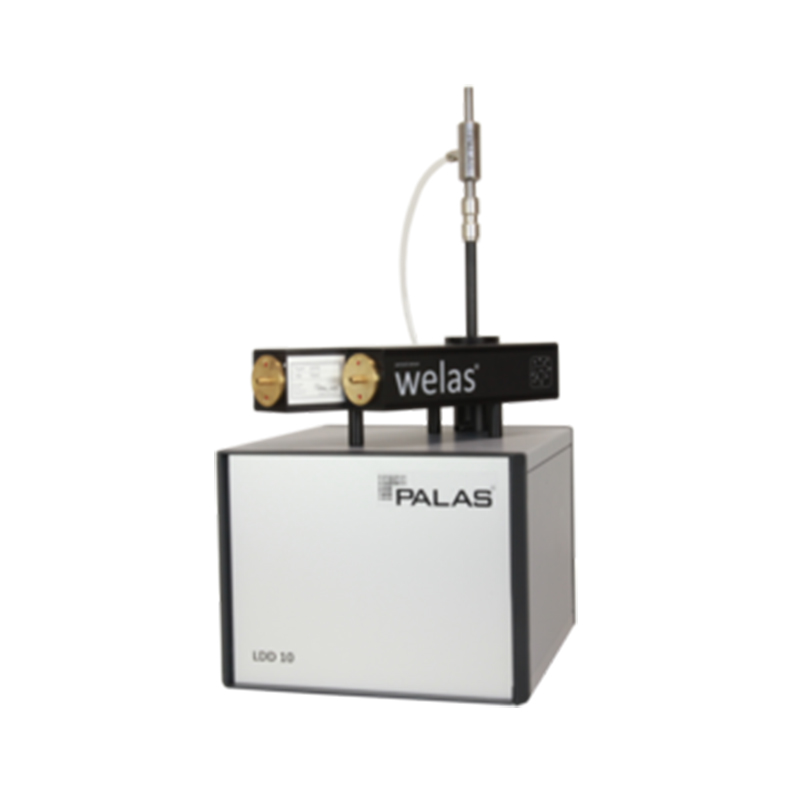

welas® 2070 aerosol sensors:

The welas® 2070 high concentration sensors ensure unambiguous and coincidence-free fractional separation efficiency measurement at the high concentration of 1000 mg/m3. These sensors are also fitted with a special aerosol guide that minimises contamination of the internal optics.

Software:

Various differential pressure levels can be set in the filter media test sequence program for loading in accordance with ISO 5011. The clear definition of the test parameters in the pre-programmable sequence programs ensure very high level comparability of the results.