Description

Depending on the composition of the aerosol to be measured, i.e. the carrier gas component and the particle material, pressure changes in the carrier gas can significantly influence the particle size distribution and the particle concentration, e.g. due to condensation or evaporation.

For this reason, the aerosol sensors welas® 2070 P through to welas® 2500 P are equipped with a pressure-resistant cuvette to ensure isobaric sampling down to the sensor’s measurement volume.

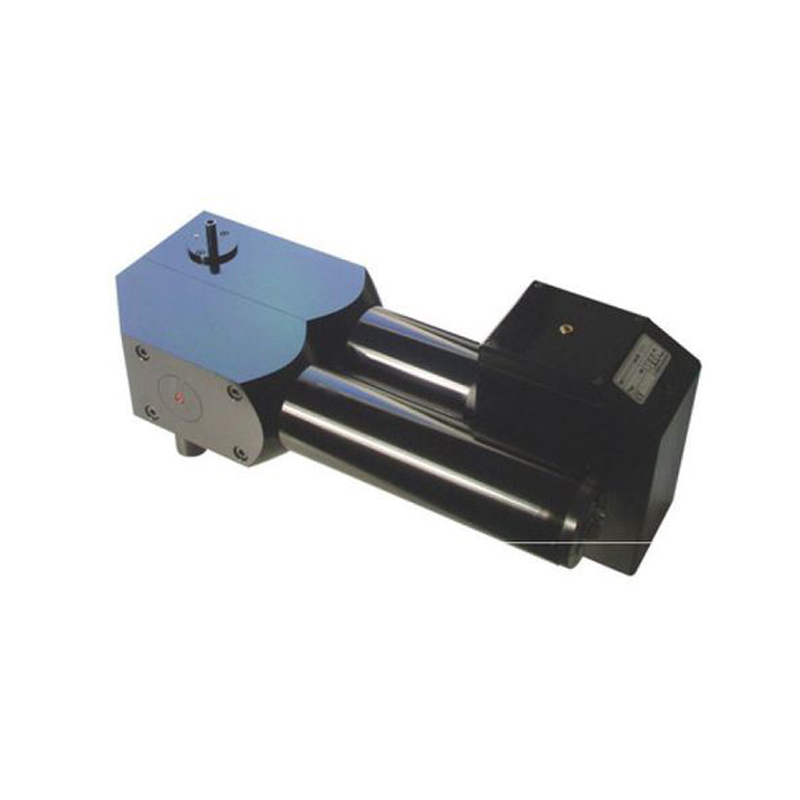

Figure 1: Pressure-resistant welas® cuvette

The cuvettes are made of eloxed aluminium (black) by default. If the sensor is used in aggressive and corrosive aerosols, the cuvette can be made of stainless steel or other special materials, such as Hastelloy.

Sealed additional disks prevent aerosol from the cuvette from escaping into the surroundings. This even offers an advantage to the measuring of toxic substances under ambient pressure.

The additional disks are easy to clean and replace by the operator.