Description

The model 2100 aerosol sensors are equipped with a small measurement volume and are used for coincidence-free measurement with a maximum number concentrations up to 500,000 particles/cm3 .

Measuring range: 0.2 – 10 µm / 0.3 – 17 µm / 0.6 – 40 µm.

Functional principle:

welas® digital and Promo® digital are based on scattered-light analysis on a single particle. The particles to be measured pass through a T-shaped, optically delineated measuring volume that is illuminated by a white light source. This generates a scattered-light pulse whose level is a measure for the concentration.

The high size classification accuracy and the high size resolution are guaranteed by the following special feature:

• White light and 90° light-scattering detection

→ unambiguous calibration curve

• Patented T-aperture technology for a T-shaped measurement technology

→ no border zone error

• New digital individual signal processing for the analysis of the scattered-light pulse

→ coincidence detection and correction which enables measurement in up to 5 times higher concentrations

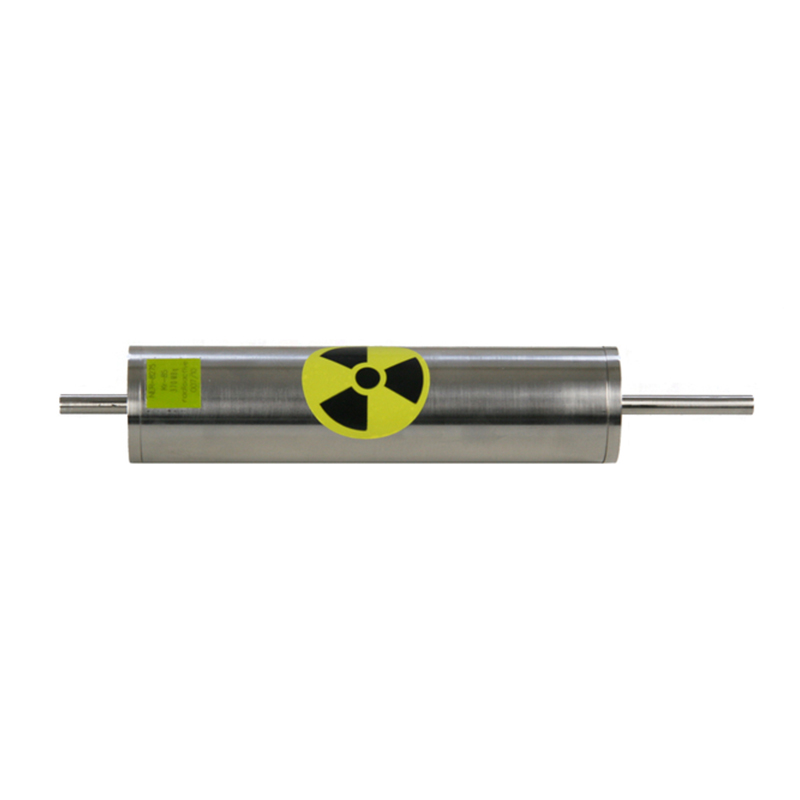

Example: the welas® sensor aerosol guide heatable up to 250°C (see variations)

Trouble-free and reliable measurement of large particles up to 40 µm in the sensor is guaranteed by the vertical aerosol duct at a high volume flow of 5 l/min and a large sampling tube diameter.

Size limitation of the optical measuring volume

The table below shows the theoretical minimum separation of the particles at a given number concentration.

At a number concentration of 103 per cm3 the optical measuring volume must not be larger than 1 mm3 .

The customer can select a sensor with the appropriate measuring volume size depending on the concentration to be measured.

For concentrations up to 1,000,000 particles/cm3 the welas® 2070 sensor with a small measuring volume is used. This ensures the smallest measuring volume such that only one particle ever enters the measuring volume. In low concentrations, the models with a larger measuring volume offers the advantage of a higher counting rate at the same number concentration.

Agreement of the sensors

The welas® sensors are characterized by a particularly good agreement of counting efficiency and particle size resolution.

This means that the measurement results are highly comparable in terms of the number concentration and particle size measured when using different sensors.

Graph 1: Counting efficiency of various sensors in relation to the welas® 2200 sensor (in the measuring range 0.2 – 10 µm)

Pressure-resistant and heatable aerosol sensors with a special cuvette for the variants P, H and HP

Special measuring cuvettes allow the use of the welas® aerosol sensors even under unusual measuring conditions. These are available:

• heatable sensors up to 250°C; higher temperatures on request

• pressure-resistant sensors up to 10 bar overpressure

• sensor resistant against chemically aggressive media