Description

Unlike the AGF 2.0, the AGF 2.0 D is pressure-resistant up to 10 bar positive pressure and is thus able to be used for applications with an absolute pressure value of up to 11 bar, e.g. to test compressed air filters and optical flow measurement procedures with positive pressure values of up to 10 bar.

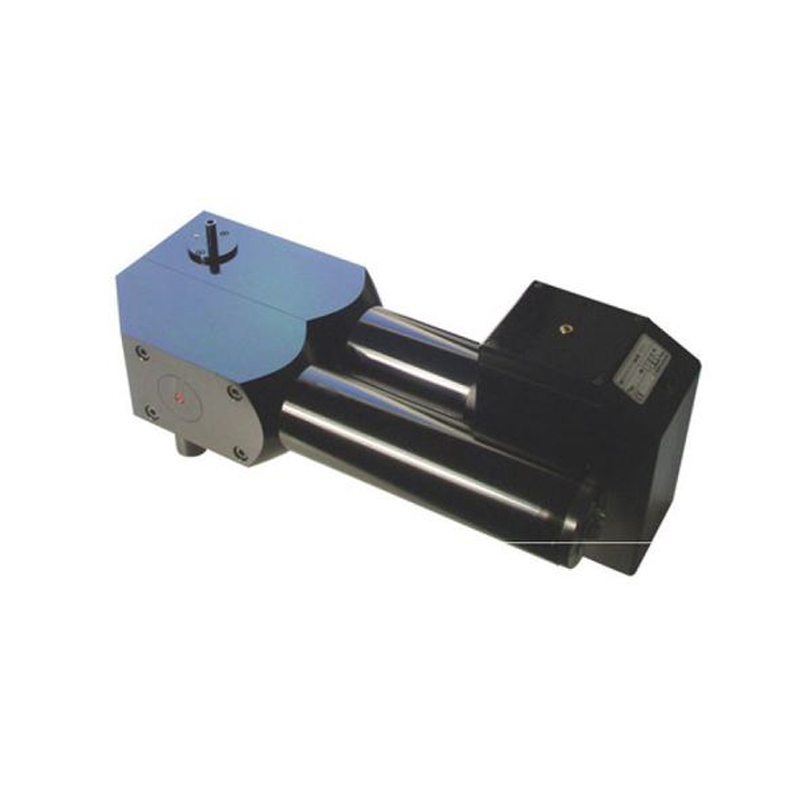

Fig. 1: AGF 2.0 D

The AGF series aerosol generators are able to atomize liquids with a binary nozzle. Fig. 2 presents a schematic arrangement of the AGF 2.0 D generator components:

Fig. 2: Schematic diagram of the aerosol generator

The AGF 2.0 D comprises an adjustable binary nozzle for adjustment of the desired mass flow and a cyclone with a cut-off of 2 µm. As a result, virtually no particles > 2 µm are generated.

Startup

Compressed air is supplied to a binary nozzle. The primary pressure on the nozzle is able to be adjusted to between 0 and 10 bar above the ambient pressure The volume flow through the AGF 2.0 D should be determined using a pressure-tight flow meter. The volume flow must be between 12 and 22 L/min. The negative pressure in the nozzle suctions the liquid to be atomized from a reservoir, while the volume flow of this liquid is able to be adjusted using a needle valve that is incorporated into the nozzle.

Table 1: Overview of the AGF and UGF systems