Description

The AGF 2.0 iP aerosol generator is able to atomize liquids with a binary nozzle.

Unlike the other versions in the AGF series, the AGF 2.0 iP is equipped with a built-in pump that generates volume flow, making an additional compressed air connection unnecessary in order to operate the device.

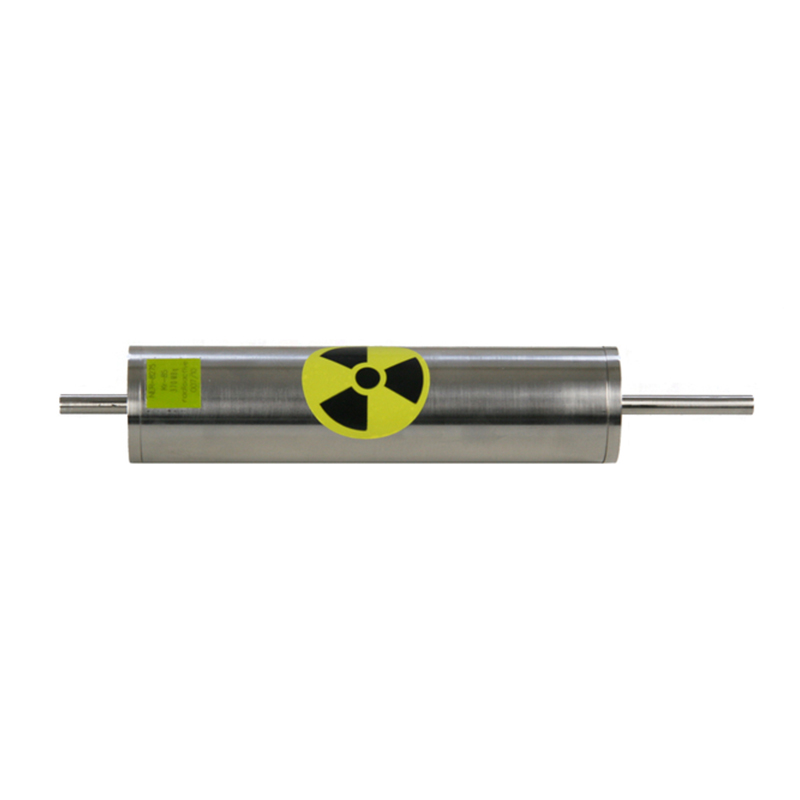

Fig 1: AGF 2.0 iP

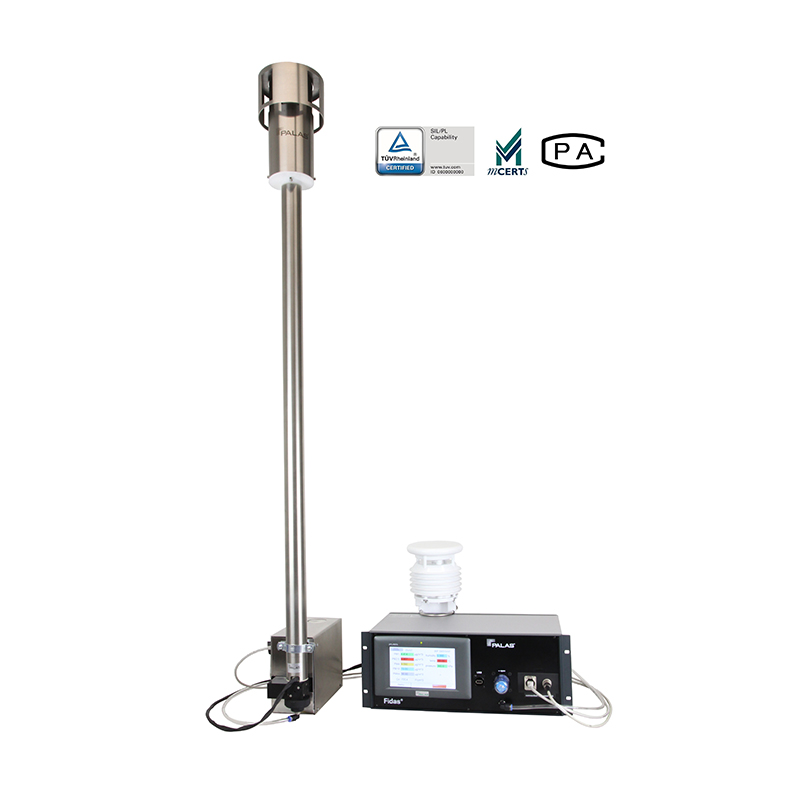

Fig. 2 presents a schematic arrangement of the generator components.

Fig. 2: Schematic diagram of the AGF 2.0 iP aerosol generator

Startup

A built-in pump suctions ambient air via a prefilter and directs it to a binary nozzle via a particulate air filter. The primary pressure on the nozzle is 0.6 bar above ambient pressure. The negative pressure in the nozzle suctions the liquid to be atomized from a reservoir, while the volume flow of this liquid is able to be adjusted using a needle valve that is incorporated into the nozzle.

Table 1: Overview of the AGF and UGF systems