Description

Unlike the PLG 2000, the PLG 2000 H is equipped with a built-in heating unit that can reach 100°C.

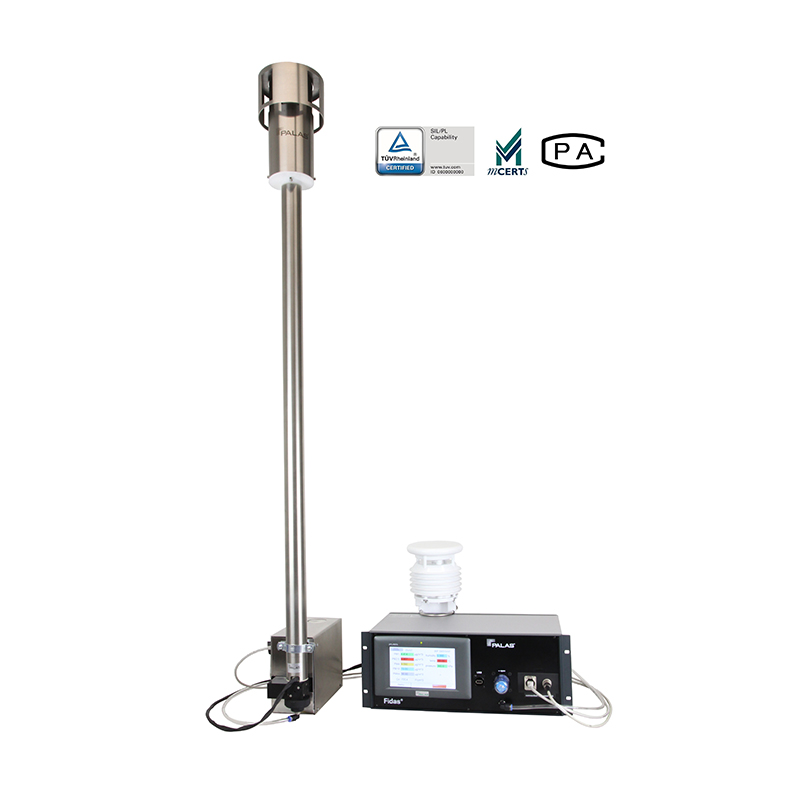

Fig. 1: PLG 2000 H

The heating of the oil changes the number concentration, as well as the particle size distribution, of the material to be dispersed due to a change in the viscosity. This additionally enables materials to be dispersed which are unable to be nebulized at cooler temperatures due to their viscosity.

The PLG 2000 H generator comprises a Laskin nozzle, a fluid heating unit, and a thermocouple to measure the temperature. The immersion tube is the aerosol outlet. The aerosol is transported to the application site through an attached tube. The liquid to be nebulized can be heated up to 100°C.

The PLG 2000 H conforms to the requirements of the EN 779 standard for ventilation filters. In addition, the PLG 2000 H can be used to test oil nebulizers.

Fig. 2: Schematic diagram of the PLG 2000 H aerosol generator

Startup

The liquid to be dispersed is simply filled in the reservoir. The nozzle system developed by Palas® is immersed in the liquid. This nozzle system is based on the Laskin principle and guarantees extremely precise dosing constancy with uniform particle size. The mass flow is adjusted using the volume flow through the nozzle. The volume flow is controlled by a pressure regulator and a manometer on the device.