Description

Low-concentration solid particle aerosols produced from powders are required for many applications in research, development, and quality assurance and for the calibration of particle measurement devices.

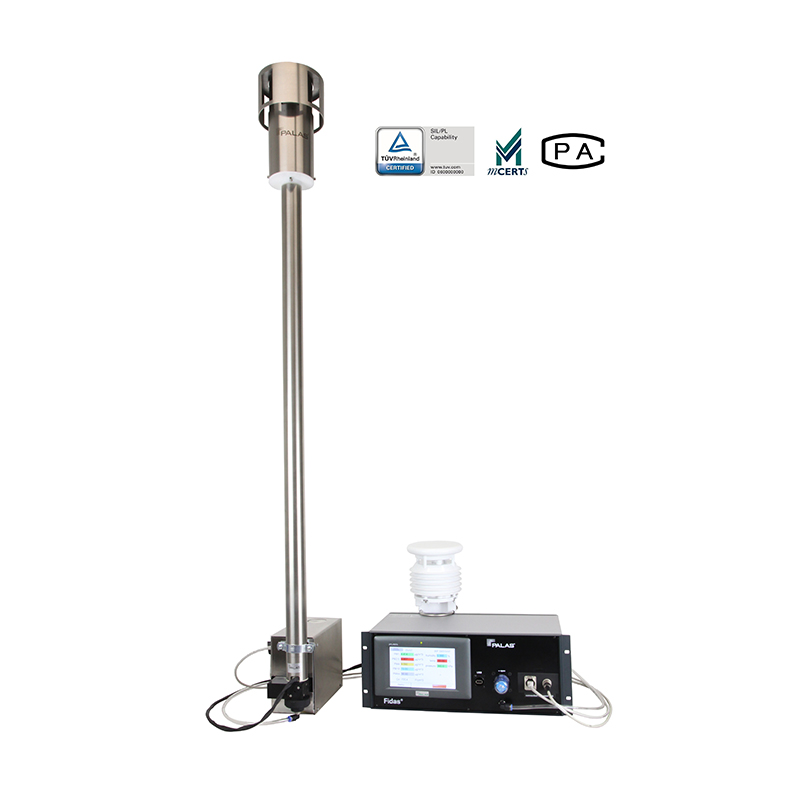

For more than 25 years, the RBG system has been used worldwide with great success for the reliable dispersion of non-cohesive powders such as mineral dusts, active pharmaceutical ingredients, pollen, etc. in the size range of < 100 µm and with a fine fraction of < 100 nm. Monolithic solid materials such as blackboard chalk are finely dispersed with highest dosing constancy.

The special advantage of this dosing and dispersion system is that in the case of the RBG 1000, mass flows ranging from approx. 10 mg/h up to approx. 430 g/h are dispersed with the highest level of dosing constancy thanks to quick, easy exchange of the solid material reservoir. The fill level of the feed stock reservoir is 70 mm.

Optional:

• Pressure-resistant up to 3 bar

• New: Low pressure operation from 300 mbar (absolute pressure), operation with nitrogen

Start-up

The powder to be dispersed is filled little by little into the cylindrical solid material reservoir and compressed with a tamper. In the context of the validation of the guideline “Prüfverfahren für mobile Raumluftreinigungsgeräte” at the Lucerne University of Applied Sciences and Arts an excellent reproducibility of the tamping density in the solid material reservoir was determined. The deviation of the tamping densities of five fillings was just 3.4 %.

The filled solid material reservoir is inserted into the dispersing head of the RGB, and the powder, which has thus been uniformly compressed across the filling level, is conveyed onto a rotating brush at a precisely controlled feed rate. An adjustable volume flow streams over the tightly woven precision brush at a very high speed and tears the particles out of the brush.

The entire material delivered can optionally be determined gravimetrically with the RBG 1000 L.

The dispersing head assembly comprises a dispersing head, dispersing cover, precision brush, and solid material reservoir.

Fig. 1: Schematic diagram of RBG system

Dosing

Dosing is performed via the precisely controlled feed rate of the feed piston. The desired mass flows can be easily and reproducibly specified based on the cross section of the solid material reservoir, the precisely adjustable feed rate of the feed piston and the easy-to-determine tamping density of the powder in the reservoir.

Table 1: Mass flows of RBG system (compacted density 1 g/cm3)

Dispersing

The powder separated from the reservoir by the precision brush is almost completely dispersed into the constituent particles, down to < 100 nm (see Fig. 2), in the dispersing head by the dispersing air flowing at high speed.

Fig. 2: Particle size distribution with the welas® digital 2000

Fig. 3: Dispersing covers, type A,. type B and type C

Four different dispersing covers can be used for optimal dispersion (see Fig. 3, additional details under “Accessories”).

Table 2: Dispersion covers

Table 3: Different versions of the RBG system

I = version for inhalation D = pressure-resistant G = low feed rate L = easily removable and weighable dosing unit S = nitrogen version

Pulse mode

The construction design of the RBG system allows for operation in “powder”/”no powder” pulse mode with cycle lengths ranging down to a second. The function can be set manually via the “Stop/Start”, and “Forward” keys or automatically via an electric timer switch.

All RBG versions can be optionally controlled via remote control or via computer.