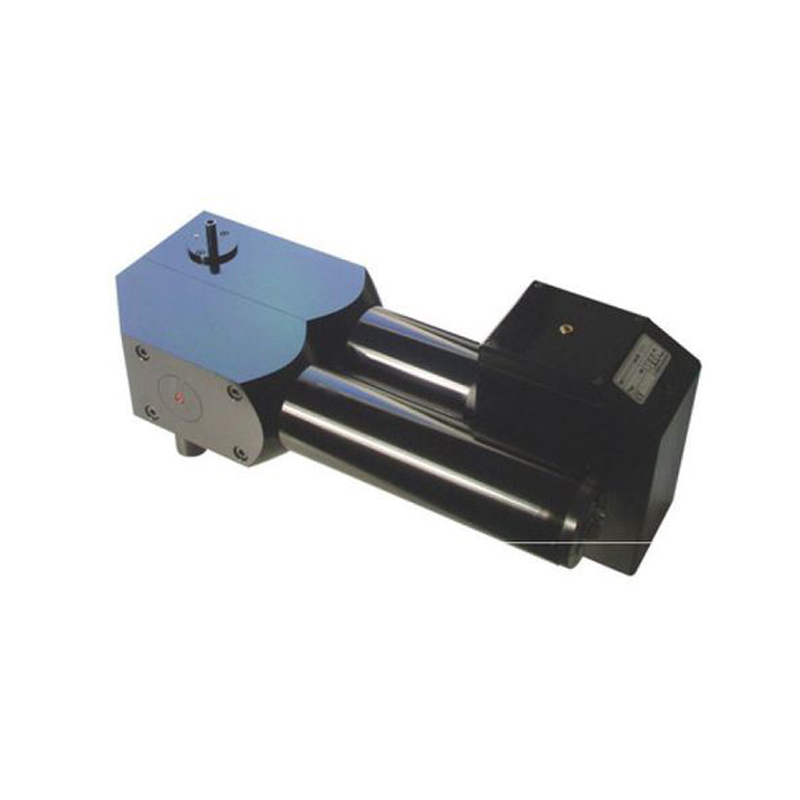

Description

This device disperses particles at positive pressure values of up to 3 bar. Optional operation with low pressure from 300 mbar absolute is possible (please see accessories).

Please note: The feed stock reservoirs with a diameter or 7, 10, 14 or 20 mm are pressure-resistant.

For operation with low pressure special pressure-resistant feed stock reservoirs are needed. Their piston is strongly connected to the feeding unit by a claw. This enables an undisturbed operation with low pressure. Old RBG models can be upgraded with this function by Palas®.

The solid material reservoir with a diameter of 28 mm is not pressure-resistant, but can be used with the RBG 1000 D under atmospheric conditions.

Nitrogen cannot be used as the dispersing gas in the pressure-resistant version of the RBG 1000.

Table 1: Mass flows of RBG system (compacted density 1 g/cm3)

Table 2: Dispersion covers

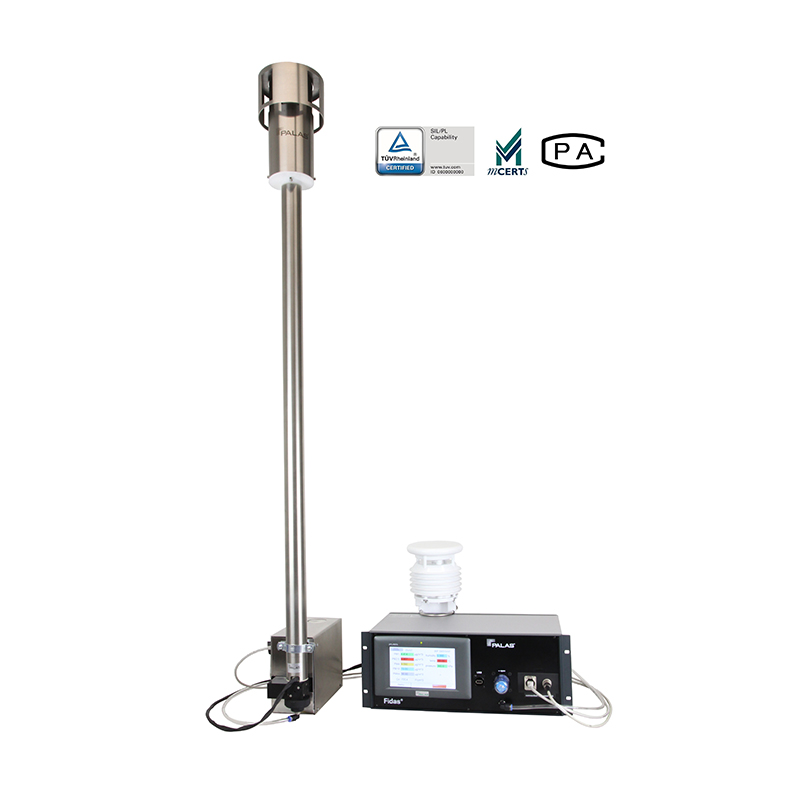

Table 3: Different versions of the RBG system

I = version for inhalation

D = pressure-resistant

G = low feed rate

L = easily removable and weighable dosing unit

S = nitrogen version