Description

Depending on the composition of the aerosol to be measured, i.e. the carrier gas component and the particle material, pressure changes in the carrier gas can significantly influence the particle size distribution, e.g. due to condensation or evaporation.

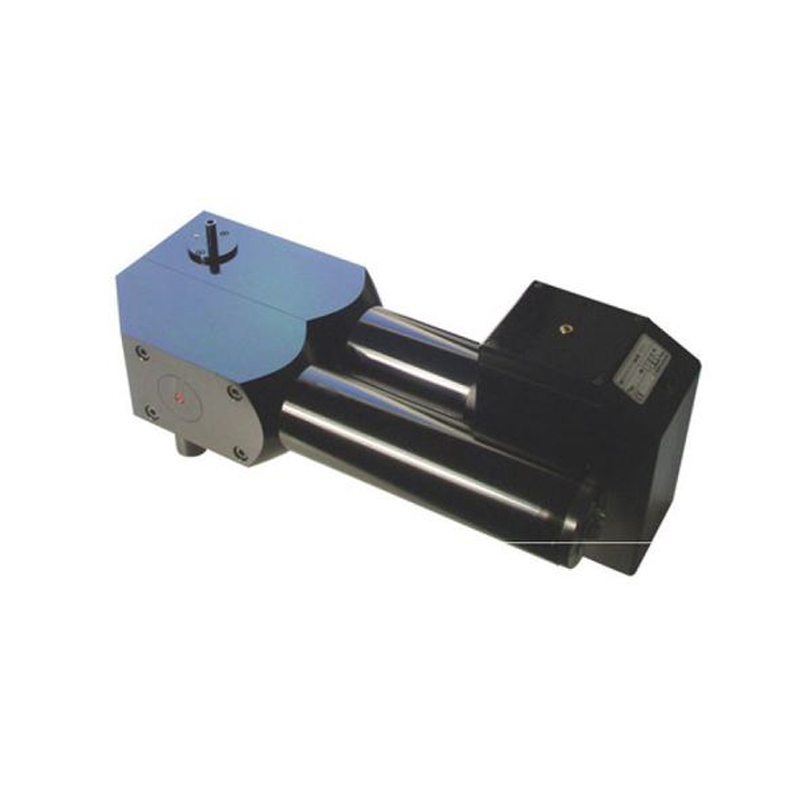

For this reason, the welas® aerosol sensors welas® 2070 P, 2100 P, 2200 P, 2300 P and welas® 2500 P are equipped with a pressure-tight cuvette to ensure isobaric and isothermal sampling into the sensor’s measurement volume.

The welas® digital is usually calibrated for the operating volume flow. As the operating volume flow changes with pressure, it is advantageous for the user if automatic volume flow regulation for the sampling volume flow is provided for in the device.

In the welas® 2000 P the pressure of the carrier gas is measured and the required operating volume flow is automatically set to 5 l/min.

Includes:

• Mass flow controller for volume flow regulation

• Absolute pressure capsule

• Filter unit