Internal combustion engines are power machines that are often used in various types of transport vehicles. It is a heat engine that burns the fuel inside the machine and converts its heat energy directly into electricity. The ever-improving oil mist separators in internal combustion engines require high-resolution measurement technology. With the modular Palas® HMT 1000 series test system, oil separators (e.g. for the separation of blow-by aerosols in combustion engines or for the separation of oil mist downstream of compressors) are characterized quickly and accurately and, in particular, successfully tested by isothermal particle measurements up to 120°C and isobaric up to +/- 200 mbar under practice-relevant conditions.

Translated with www.DeepL.com/Translator (free version)

Palas® HMT 1000 for BASF Automotive Testing Laboratory

Stable Measurement. Green Production

Back in 2017, the Automotive Testing Laboratory affiliated with the BASF Performance Materials Asia Pacific Engineering Plastics Innovation Center ordered the Palas® HMT 1000 heatable modular testing system for oil mist separators. In order to better conduct tests, BASF in China was looking for a solution that would provide reliable measurement results. As colleagues at the French headquarters had good experience with Palas® equipment and recommended it, the Automotive Testing Laboratory in China chose the Palas® HMT 1000.

Palas® HMT 1000 for BASF Automotive Testing Laboratory

Oil separators must be clearly characterized in terms of their effect on efficiency at different temperatures, i.e. at different particle sizes and particle concentrations, and at different volume flows. Time-dependent changes caused by the volume flow must be clearly characterized by reliable online measurements. For example, in the separation of blow-by aerosols in combustion engines or in the separation of oil mist behind compressors. With the HMT 1000, the isothermal particle measurement process can be tested quickly and precisely at temperatures up to 120°C. BASF was convinced that the test results obtained with the HMT 1000 can show whether the design of automotive parts meets the qualification requirements of OEMs. This is very important because current emission requirements are relatively strict, and laboratories must measure whether or not products meet the high emission standards

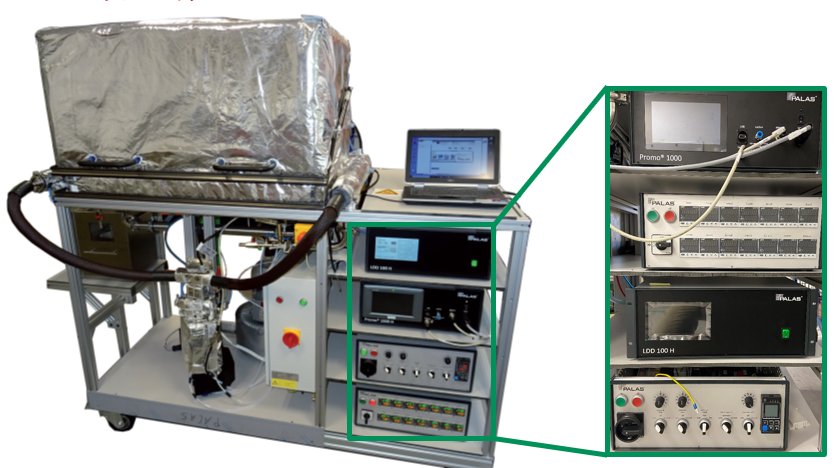

Main control unit and temperature control

Palas® Defines A New Method of Measurement

Most household meters use the quantitative gravimetric determination method, and data analysis is performed by weighing the oil consumption. However, oil consumption can cause errors in many steps of the experimental process. Conventional quantitative gravimetric determinations are often not fast or sensitive enough and do not provide information on particle size distribution. The HMT 1000’s testing system is advanced and can reduce errors in the measurement process. Thanks to the excellent correlation between the quantitative distribution measurement and the gravimetric analysis, very fast and volume-relevant testing of oil mist separators is guaranteed. For example, the determination of the ultrapure mist concentration can be performed within 1 minute using the Promo®1000 H system occupied on the HMT 1000.

Innovative Technology. Reliable Results.

The heart of the HMT 1000 is the Promo® 1000 H scattered light aerosol spectrometer, which independently and simultaneously measures particle size, particle number and thus concentration. Stability and accuracy at high temperatures is an important part of the measurement process. With Promo® 1000 H, the HMT 1000 is equipped with an isothermal measurement technique that effectively solves the problem of low accuracy and reliability in oil mist separation rate measurement.

The HMT 1000 thus underlines its position as an innovative device in the field of research from the measurement principle. In the future, Palas® measuring instruments will continue to be at the cutting edge of technology to meet the demands of today’s parts manufacturing industry.

HMT 1000 Test Rig

Benfitens

· Measurement and evaluation of fraction separation efficiency and burden

· Isothermal and isobaric measurement

· All components can be heated to 120°C

· High reproducibility of the testing method

· Internationally comparable measurement results thanks to the widespread use of the measurement system

· Cleaning and calibration can be performed autonomously by the customer

· Easy to operate, even untrained personnel can be instructed quickly in the use of the equipment

· Modular layout offers increased flexibility

· Validation of the clear function of individual components and the overall system during pre-delivery acceptance testing and upon delivery

· Reliable operation

· Short set-up times, extremely low-maintenance

· The unit will reduce your operating costs

Applications

· Quality assurance for oil separators

· New and further development of oil separators, e.g. coalescence separators, cyclonic separators and other inertia separators, electrofilters and filter combinations, e.g. for

– Blow-by aerosols

– Oil mist downstream of compressors

– Cooling lubricants on machine tools

– Aerosols for minimal quantity lubrication

Palas® China will arrange a series of online webinars both in English and Chinese for Ambient air quality continuous monitoring system, Palas® SMPS scanning mobility particle sizer, Palas® Promo® & Aerosol Generator & Dilution system, ISO 16890 filter media tester, Palas® MFP 3000 G, ISO 29463-3 filter media tester, Palas® MFP Nano plus 4000, ISO 17536 Fractional filtration efficiency tester of Oil Mist Separator, Palas® HMT 1000, as well as Particle Distribution Measurement Devices Introduction – Optical Scattering Method and many other solutions. If interested in the webinars for our products, you are more than welcome to register on our official website and get the latest webinar plan!