Filter media made of different formulations require suitable filtration performance monitoring instruments to measure. Palas® filter media testing instruments excel in filtration efficiency monitoring. Relying on the good reputation of Palas® in the field of scientific research, Tianjin Key Laboratory of Pulp and Paper from Tianjin University of Science and Technology chose Palas® MFP 3000 filter media filtration performance test rig. Applied in the research project “Lab‑scale design of two layers wood cellulose filter media to maximize life span for intake air filtration”. The Palas ® MFP 3000 has the advantages of modular design and compliance with multi-standard test specifications and also helped the research team to obtain stable detection data in the measurement of single-layer and two-layer filter media.

Measurement needs of research teams

The Tianjin Key Laboratory of Pulp and Paper responsible for this research project is affiliated to the Pulp and Paper Engineering discipline of Tianjin University of Science and Technology. It is a ministerial-level key laboratory of the former Ministry of Light Industry and the former Light Industry Association. For this project, the sustainability of filtration performance, service life, overall efficiency, initial pressure drop and cost-effectiveness were studied. The Tianjin University of Science and Technology scientific research team selected three types of commercial cellulose and adjusted the ratio of the top layer pulp. Filter media composed of single-layer and two-layer were fabricated and measured, and the effect of cellulose blending on physical properties and filtration performance was analyzed.

Both the thickness and the air permeability of the two-layer filter media are higher than those of the single-layer media. Therefore, stable monitoring instruments are required to perform the measurement. For this reason, Tianjin University of Science and Technology chose the Palas® MFP 3000 filter media filtration performance test rig that meets the standard of “ISO 5011 Performance Test of Air Intake Cleaning Devices for Internal Combustion Engines and Compressors”.

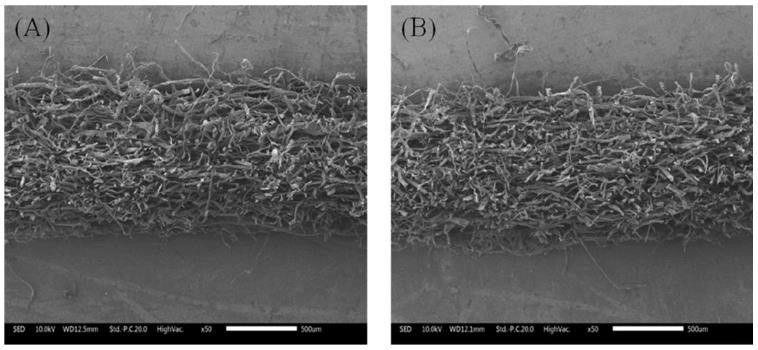

Figure 1. Cross section scanning electron microscopy images of dual layers filter media (A) and media(B).

Extensive filter media detection

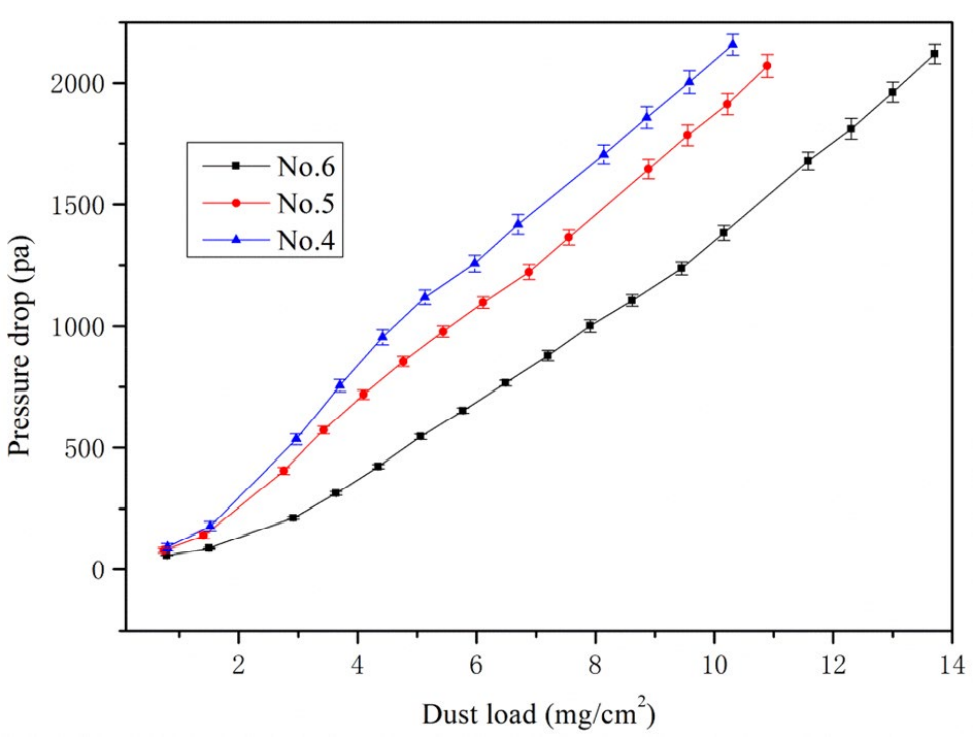

In the experiment, MFP 3000 conducts a filtration performance comparison test on filter media made of different formulations according to ISO 5011 standard and validated double-layer filter media products made by the new process. It is measured that its performance life has increased by 37% and its dust holding capacity has increased by 34.7%.

Data support provided by Palas® MFP 3000 filter media filtration performance test rig:

Figure 2. The relationship of dust load with pressure drop at face velocity 11.1 cm/s.

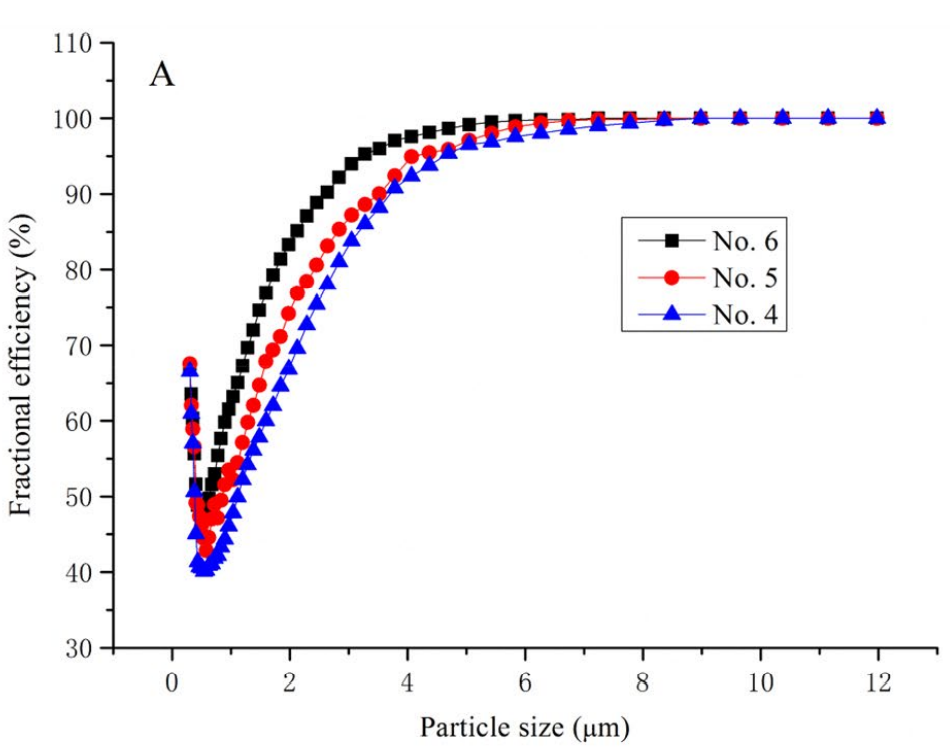

Figure 3. Fractional efficiency of different particle size at 69 s

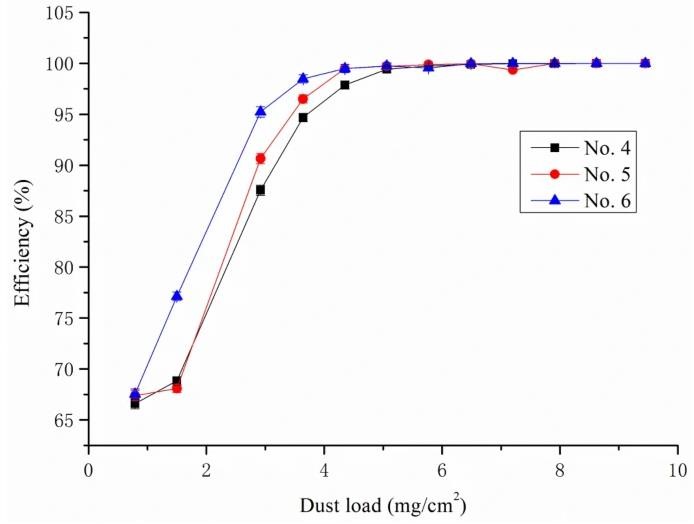

Figure 4. Overall efficiency of 0.305 μm particle size dust at face velocity 11.1 cm/s.

The modular design of the Palas® MFP 3000 is ISO 5011 compliant. Monitoring can also be performed according to EN779, ASHRAE 52.2, DIN 71460-1, ISO TS 11155-1, EN 1822, ISO 29463 and more. At the same time, the following performance indicators can be monitored according to different test filter materials of users:

- Pressure drop curve

- Initial classification efficiency

- Classification efficiency in load step-by-step loading

- Dust holding capacity

- Gravimetric filtration efficiency

- Most easily permeable particle size (MPPS) and corresponding filtration efficiency.

MFP 3000 is a modular filter media test rig for fractional efficiency, differential pressure, dust holding capacity and gravimetrical efficiency in suction mode. Version HF is equipped with temperature and humidity control. MFP 3000 has an integrated mass flow controller that it can be used to control the volume flow. The volume flow rates are automatically monitored and controlled by the FTControl filter test software. The data from the integrated sensors – such as the volume flow, temperature, relative humidity and differential pressure at the filter are also recorded automatically during the filter test.

If you are interested in the filtration performance of Palas® MFP 3000-assisted double-layer lignocellulose filter media. Please click for the paper details.

Palas® MFP 3000 filter media filtration performance test rig

Advantages

· Virtually simultaneous measurement of upstream and downstream particle

· Particle size measurements from 0.2 – 40 µm

· Measurement of Cn max= 106 particles/cm3 without dilution

· Internationally comparable measurement results

· Widespread distribution of the measurement system

· High reproducibility of the testing method

· Easy use of different test aerosols, e.g. SAE Fine and Coarse, NaCl/KCl, DEHS

· Highest raw gas concentrations of up to > 1000 mg/m3 (ISO Fine) or > 5000 mg/m3 (ISO Coarse) with measurement of the fraction separation efficiency for burden tests

· Faster filtration efficiency testing in the process

· Flexible filter test software FTControl

· Provide the corresponding test process for different test requirements, support the selection of certain processes and test

· Easy to operate, even untrained personnel can be instructed quickly in the use of the equipment

· Cleaning and calibration can be performed autonomously by the customer

· The core products used in the test rig (e.g. generators, particle size spectrometers, etc.) can be disassembled and used for other applications

· Provide functional verification reports for individual devices and complete test rig prior to equipment delivery

· Low maintenance

Applications

· Flat filter media or small filter

· Product development and production quality management

· Tested according to ISO 11155-1 and DIN 71460-1 standards, see MFP 3000 C test rig

· Tested according to ISO 5011, see MFP 3000 M test rig

· Tested according to ISO 16890 and ASHRAE 52.2 standards, see MFP 3000 G test rig

· Tested according to EN 1822-3 and ISO 29463-3 standards, see MFP Nano Plus 4000 test rig

· Other standard or customer-defined test requirements

· Automatic measurement of graded filtration efficiency, pressure drop curve, dust holding capacity and gravimetric filtration efficiency

· Product quality control and comparison between users and upstream and downstream enterprises

Palas® will arrange a series of online webinars both in English and Chinese for Ambient air quality continuous automatic monitoring system, SMPS scanning mobility particle size spectrometer, Promo® aerosol spectrometer, Aerosol generator and Dilution system, ISO 16890 filter media test rig-MFP 3000 G, ISO 29463-3 HEPA/ULPA filter media test rig-MFP Nano plus 4000, ISO 17536 oil mist separator filtration performance test rig-HMT 1000, as well as many other aerosol test solutions. You are welcome to register for the conference and will be informed of the webinar information as soon as possible!