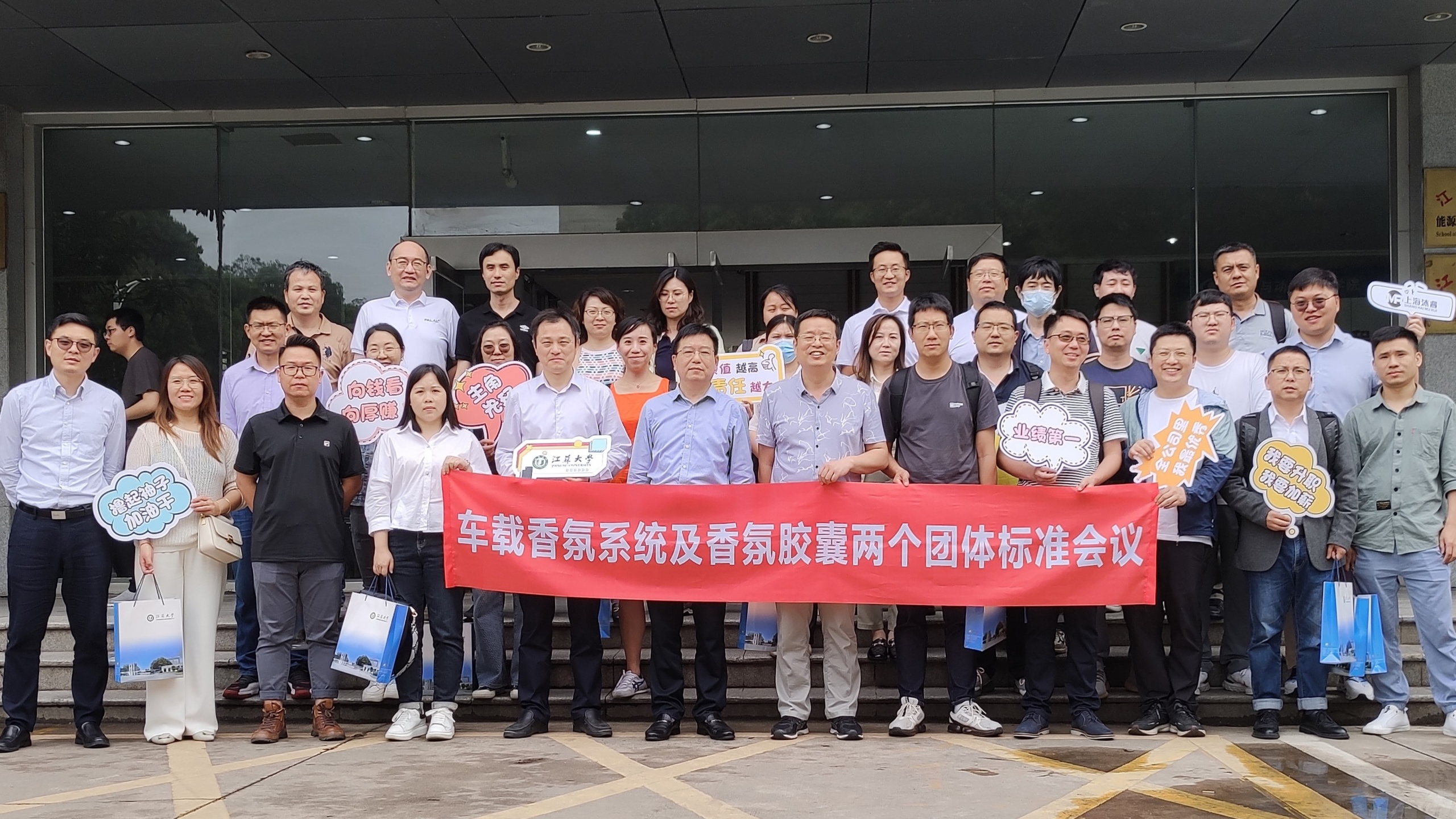

As passenger cars become more intelligent, front-mounted active fragrance systems are mature and the presence of in-car fragrance needs a major upgrade. Shanghai MuRui Technology Service Co., Ltd. and Jiangsu University jointly set up a series of group standards such as “Car Fragrance Capsule Testing Specification” and they successfully held the “2023 Car Fragrance Capsule Testing Specification Group Standard Launch Meeting” on 27th May 2023, at Jiangsu University School of Automotive and Traffic Engineering in Zhenjiang.

Palas® had the honor to participate in this meeting and delivered a keynote speech on “Automotive particulate filtration performance testing and standards interpretation – ISO11155-1 & ISO29463-5”. Also, demonstrated a variety of particle measurement instruments and all the group standard participants conducted an in-depth exchange and discussion in order to help promote the start of the group standard project.

Precision instruments help with fragrance testing.

The source of the fragrance material is complex. With the development of fragrance processing technology, there may be more ingredients in the fragrance system. This brings air changes in the vehicle and the special nature of the vehicle environment may lead to new safety issues. So, there is a need for new testing technology to evaluate fragrance quality more accurately and objectively, to protect driving safety.

To further enhance the understanding of testing and standards, Mr. Linus Wang, Sales Manager of Industry and Science at Palas® China, gave an in-depth explanation. According to the introduction, Fidas® Frog uses the recognized measurement technology of optical light scattering of single particles. It can accurately measure the particle size distribution and PM information inside and outside the car and can individually set the mass concentration limits of various PM components to help further monitor the fragrance.

Palas® AQ Guard provides an accurate and reliable assessment of in-vehicle air quality and infection risk. The machine can monitor CO2 concentrations and VOCs in combination and monitoring the air quality in the car with particle size distribution and concentrations of particle sizes 150 nm and larger.

The multi-standard-compliant Palas® filtration performance test rigs can help you gain photometric total penetration. It is tested over the particle size or the particle size-dependent penetration. Differential pressure measurements and loading tests or gravimetric measurements, based on different standards, are also possible thus effectively testing the filtration performance of in-vehicle air filters and helping to obtain a reliable Chinese auto health index.

The test rigs of the FET systems enable a reliable control of complete filter elements up to a size of 610 • 610 • 610 mm. It tests better than required by numerous standards, e. g. ISO 11155-1 and DIN 71460-1/-3 standards. The instrument works with different dust, salt, oil as well as latex aerosols over a size range from 0.02 to 40 µm. FET systems can effectively measure a large number of particles in the car with a filtration effect of 99.9995%.

As one of the indispensable products in the automotive industry, car fragrances need to continuously standardize their safety standards. Palas®, as an expert in the field, will continue to contribute to the development of China’s motor vehicle safety inspection by performing accurate measurements.

Fidas® Frog Fine Dust Measurement Device

Fidas® Frog is a compact and lightweight design and can be used as a portable hand-held monitor. It can be powered by either battery or normal power outlets and can work for up to 8 hours per battery charge. Based on these features, it allows a flexible application at any measurement site.

Advantages

· Continuous and simultaneous real-time measurement of PM1, PM2.5, PM10 and TSP-values

· Additional particle number concentration and particle size distribution

· Wide measuring range: 180 nm – 100 µm

· Adjustable time resolution from 1 s

· Direct comparison of different measurements

· Configuration of limit values possible

· High quality of measuring data through the implementation of the sensor/evaluation algorithm of EN-certified Fidas® 200

· Additional expanded range of applications by possible separation of the measuring device and the Tablet-PC for control (communication via WLAN)

· Up to eight hours of measurement time in battery mode

· Ergonomic design and low weight

· Intuitive and simple operation

· Integrated camera for the documentation of the measurement)

· Export function for measured data

· Possibility to generate a measurement report as pdf in Fidas® Frog

· Remote monitoring and control via network integration are easily possible

Applications

· Fine dust monitoring at alternating locations or in movement

· Air quality monitoring indoors, at the workplace, or inside vehicles

· Use as an aerosol spectrometer in setups where space is limited

AQ Guard Ambient Air Quality Monitor

Advantages

· Technology based on the type approved Fidas® 200 series (EN16450 and MCERTS)

· Simultaneous measurement of Cn, PM1, PM2.5, PM4, PM10

· High accuracy due to advanced algorithms

· Operates on AC, DC, or power-over-Ethernet

Applications

· Industry: production process, bulk material handling (mixing, unloading, storage, packaging, etc.), and factory boundary monitoring

· Construction site: road, railway, demolition site

· Buildings: schools, kindergartens, hospitals, hotels, offices, public service buildings

· Residential buildings near construction sites or other contaminated areas

· Public transportation: airports, railway stations, tram and subway stations, cruise ships, cabins

FET System Test Rigs for Filter Elements

Advantages

· Customization of filter adapters, flow channel, and measuring ranges possible for optimal test performance

· Applicability of many test standards in one device

· Optional testing of filter media and elements by simple adapter exchange

· A simple exchange of filter elements for testing

· Reliable quality assurance due to simple operation

· Logged results based on relevant standards

· Factory-tested and calibrated test rigs

Applications

· Passenger compartment filter

· Hepa/ulpa clean room filter

· Room air filter

· Cabin filter

· Engine air filter

· Compressor supply air filter

(Source of information and some pictures: Launch meeting organizers)