Fibrous nonwoven filters are widely used for various air filtration applications. The double-layer composite filter media usually consists of a coarse and a fine layer. The coarse filter media could capture large particles and extend the lifetime of the composite filters, so it is essential to study coarse filter media.

The Nonwovens Institute at NC State University used Palas® MFP 3000 for a research project on fibrous nonwoven coarse filters. The MFP 3000 has a high dust concentration test capability as well as flexible and powerful test functions. MFP 3000 assists the team in achieving consistent monitoring data by measuring samples of dust-containing filter media in different stages.

The Nonwovens Institute at NC State University

Research teams face measurement challenges

Eunkyoung Shim, Associate Professor at The Nonwovens Institute at NC State University, and his Ph.D. student Yu Song conducted this research. They have prepared a fibrous nonwoven coarse filter composed of polypropylene (PP) and binder fiber with a blend ratio of 70:30. However, due to the lack of non-invasive and non-destructive structural characterization techniques, the research progress on the filtration performance and structure evolution of fluffy coarse fiber filter materials during loading is very limited. So they urgently needed a suitable filter media filtration performance test rig.

The test media for coarse filtration materials is usually ISO A2 fine dust with a mass concentration of up to 1,000 mg/m3. It is very challenging to measure particles accurately under such high mass concentrations. After investigation, common particle measurement devices in filtration performance testing systems require a dilution system to measure particles. The dilution systems could not be recovered well for large particle sizes (e.g., 3 μm and above); therefore, the results can vary significantly from the actual situation.

Palas® MFP 3000 is a widespread measurement system and has been well-received by university research teams. The Nonwovens Institute at NC State University also investigated the test system. They found that the white light source-based particle size spectrometer Promo® 3000 used in the MFP 3000 can accurately measure fine dust up to 1000 mg/m3 in A2 as well as coarse dust up to 5,000 mg/m3 in A4 without the need for a dilution system. This feature was of great interest to the researchers. The flexible test procedure allows the user to load the filter media with dust at a specific differential pressure.

Reliable data is essential for convincing conclusions, and the tests according to the conditions required by the standard makes the results more comparable. Palas® MFP 3000, which followed ISO 5011, meets the requirements of The Nonwovens Institute at NC State University in terms of testing standards, and it helps to analyze the loading behaviors of the studied fibrous nonwoven coarse filter media.

Test results of the Palas® MFP 3000

In this study, the researchers completed the preparation and then measured and characterized its grammage, thickness, and fiber volume percentage. Palas® MFP 3000 was then used to measure the dynamic changes in pressure drop and filtration efficiency during the dust loading process. The results of the study are shown in the three data plots below.

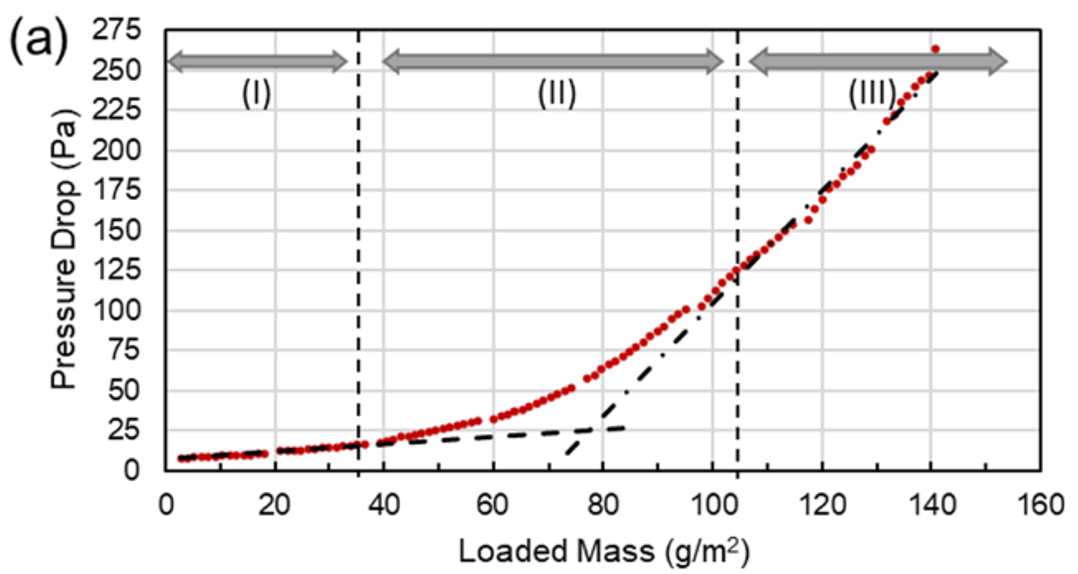

Figure a. Pressure drop vs. loaded mass.

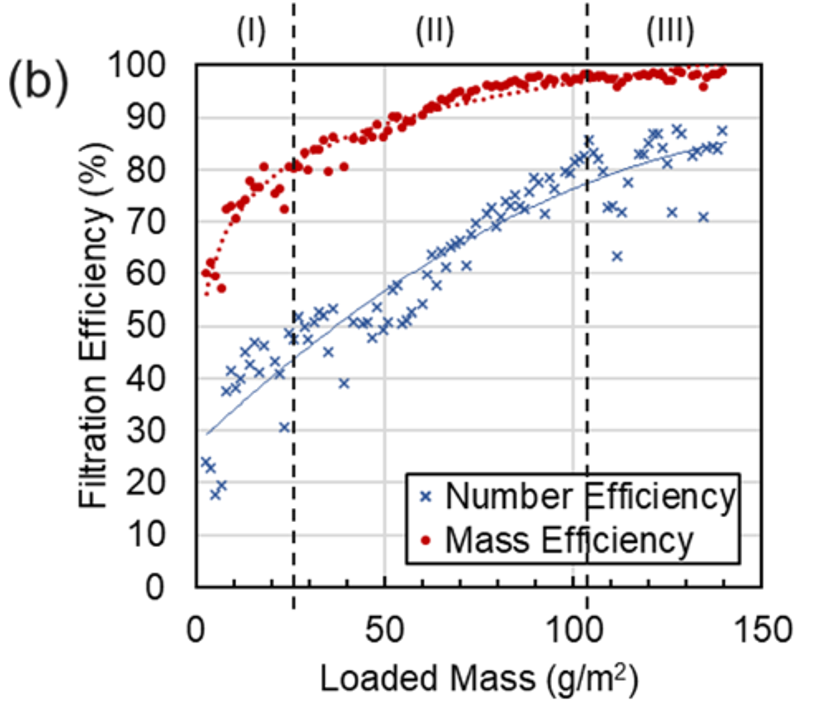

Figure b. Filtration efficiency vs. loaded mass.

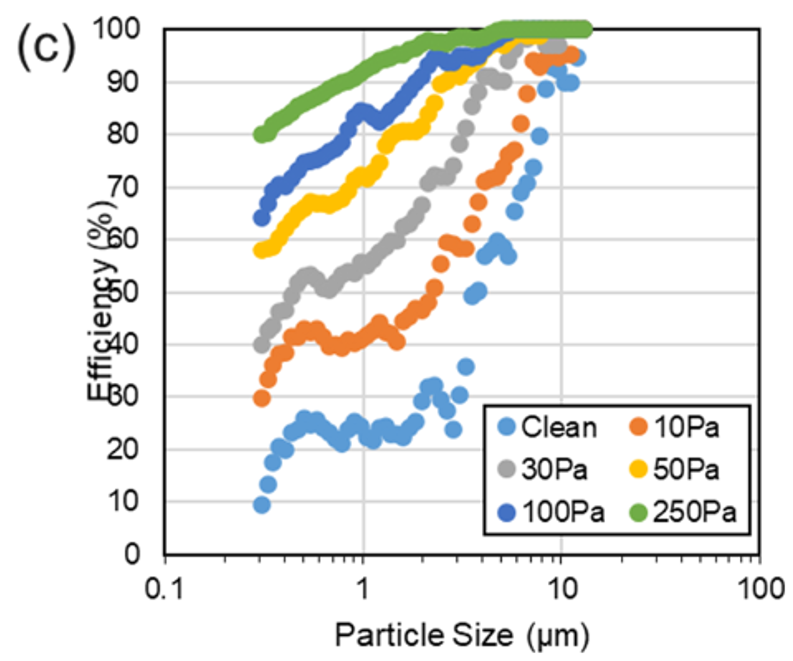

Figure c. Fractional efficiency vs. particle size at various loading stages.

Figure a. shows that the pressure drop tends to increase with dust loading over time and exhibits an initial slow increase with a subsequent increase in speed. Figure b. shows that both the quantitative and qualitative efficiencies of filtration increase with dust loading and the counting efficiency is much lower than the mass efficiency. The main reason is that the weight of large particle size in the mass concentration share is much greater than that of small particle size, which is more easily filtered. Figure c. shows the change in classification efficiency trend during the step-by-step dust loading.

Palas® MFP 3000 could measure the dynamic change of pressure drop and filtration efficiency during continuous dust loading. The observation of the coarse filter also provides a solid basis for subsequent studies of the clogging process of the fibrous nonwoven coarse filter. Palas® knowledge and expertise, the focus on supporting research, and the view of industry standards add significant value to Palas® MFP 3000, and it received technical and data support for experiments at The Nonwovens Institute at NC State University. Palas® team will continue to provide strong support for research into efficient media filtration.

Palas® MFP 3000 filter media filtration performance test rig

Palas® MFP 3000 can be used for five major items of common filter media filtration performance testing:

1.Pressure drop curve

2.Initial fractional efficiency

3.Fractional efficiency during dust loading

4.Dust holding capacity

5.Gravimetric filtration efficiency

The test system also supports testing capabilities for multiple standards. Including but not limited to ISO 5011, ISO 11155-1, DIN 71460-1, ISO 16890, ASHRAE 52.2, and EN 779, for testing the filtration performance of dust, oil, or salt particles according to different standards.

Advantages

· Virtually simultaneous measurement of upstream and downstream particle

· Particle size measurements from 0.2 – 40 µm

· Measurement of Cn max= 106 particles/cm3 without dilution

· Internationally comparable measurement results

· Widespread distribution of the measurement system

· High reproducibility of the testing method

· Easy use of different test aerosols, e.g., SAE Fine and Coarse, NaCl/KCl, DEHS

· Highest raw gas concentrations of up to > 1000 mg/m3 (ISO Fine) or > 5000 mg/m3 (ISO Coarse) with measurement of the fraction separation efficiency for burden tests

· Faster filtration efficiency testing in the process

· Flexible filter test software FTControl

· Provide the corresponding test process for different test requirements, support the selection of certain processes, and test

· Easy to operate, even untrained personnel can be instructed quickly in the use of the equipment

· Cleaning and calibration can be performed autonomously by the customer

· The core products used in the test rig (e.g., generators, particle size spectrometers, etc.) can be disassembled and used for other applications

· Provide functional verification reports for individual devices and complete test rig before equipment delivery

· Low maintenance

Applications

· Flat filter media or small filter

· Product development and production quality management

· Tested according to ISO 11155-1 and DIN 71460-1 standards; see MFP 3000 C test rig

· Tested according to ISO 5011; see MFP 3000 M test rig

· Tested according to ISO 16890 and ASHRAE 52.2 standards; see MFP 3000 G test rig

· Tested according to EN 1822-3 and ISO 29463-3 standards; see MFP Nano Plus 4000 test rig

· Other standard or customer-defined test requirements

· Automatic measurement of graded filtration efficiency, pressure drop curve, dust holding capacity, and gravimetric filtration efficiency

· Product quality control and comparison between users and upstream and downstream enterprises

Palas® organizes a series of webinars on various topics to share professional knowledge of aerosol measurement technology. Palas® technical experts and industry scholars from all over the world will give you detailed online explanations. You are welcome to register to attend and learn more about the webinars as soon as possible!

Topic: Study on aerosol concentration and particle size distribution

Time: Friday, June 2, 2023, 15: 00 – 16: 00

Speaker: Mr. Jeff Yi

Market Manager of Industry & Science at Palas® China

You are welcome to register for the conference!

Click here to register