Protective coatings are increasingly required for precision instruments in demanding environments, such as power electronics and electromagnetic motors or generators. Among them, ceramic coating is favored for its higher mechanical strength and higher temperature resistance. Aerosol deposition (AD) is a highly efficient method for the manufacture of ceramic coatings at room temperature, which can be used to directly deposit dense coatings at room temperature using fine ceramic powders. One of the breakthroughs in this process was the availability of a sophisticated aerosol generator.

Palas® RBG 1000 aerosol generator, with its stable dust generation under different pressure conditions, came to the attention of the research team at the University of Manchester. The equipment provided the team with a more continuous and stable aerosol for the production of alumina coatings using AD and offered a series of reliable test data that helped the researchers optimize the process for improving the durability of precision instruments and equipment in harsh environments.

Process optimisation in the aerosol deposition processes

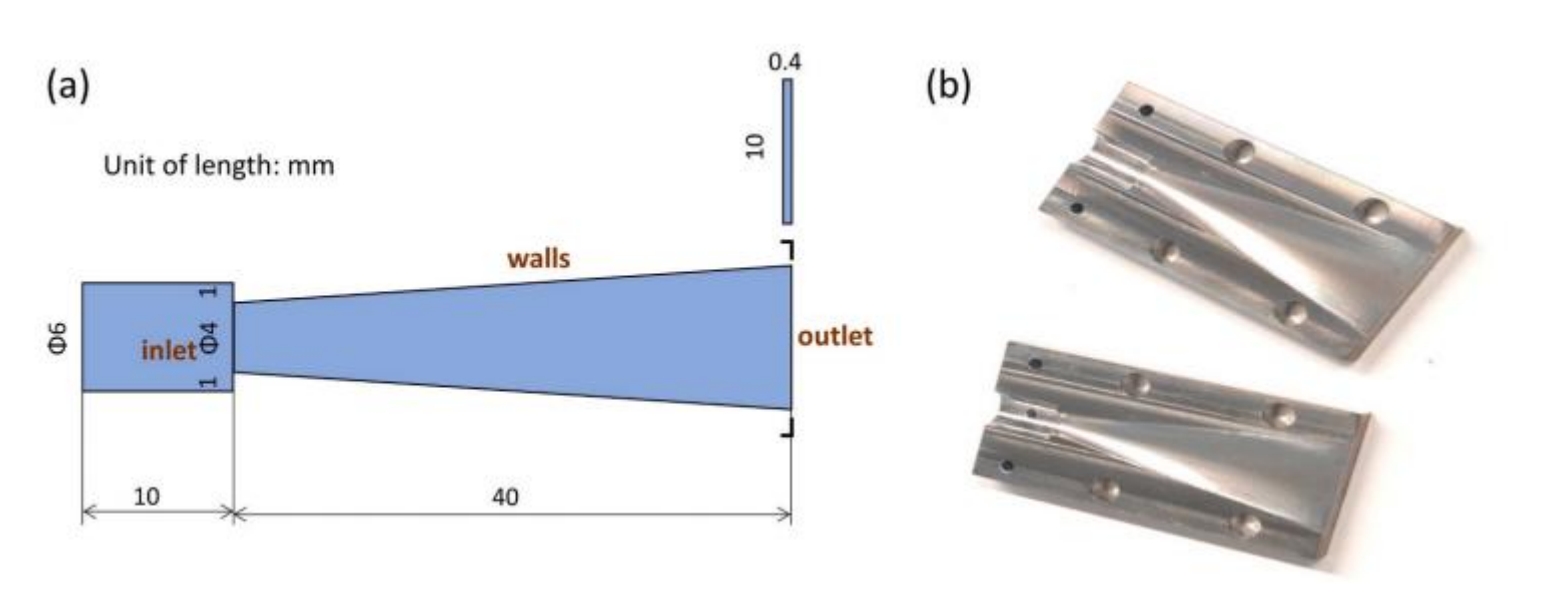

It is crucial to select a powder having the appropriate physical characteristics and evaluate the particle flow behavior during the deposition process. In the present work, they focused on enhancing the precursor powder applicability during aerosol deposition by finding suitable powder processing methods. However, obtaining the desired results for powders with different physical properties required multiple experiments at high temperatures and pressure to generate comparative data. Palas® RBG 1000 aerosol generator provided a more stable and continuous aerosol for this experiment at 10 -3 mbar, which was fed into the deposition chamber through the nozzles as shown in the figure below.

(a) Geometric dimensions and (b) image of the stainless steel nozzle used in the AD process.

The AD process can be broken down into several stages, which comprise the generation of a particulate aerosol, transport of the aerosolised particles to a substrate, impact, fracture and plastic deformation of particles to achieve final densification. After the milled powder had been processed into alumina granules by a spray dryer and atomized, dried, and collected, it was filled into the Palas® RBG 1000 aerosol generator and diffused to form a stable aerosol, which was subsequently deposited to form the alumina coating.

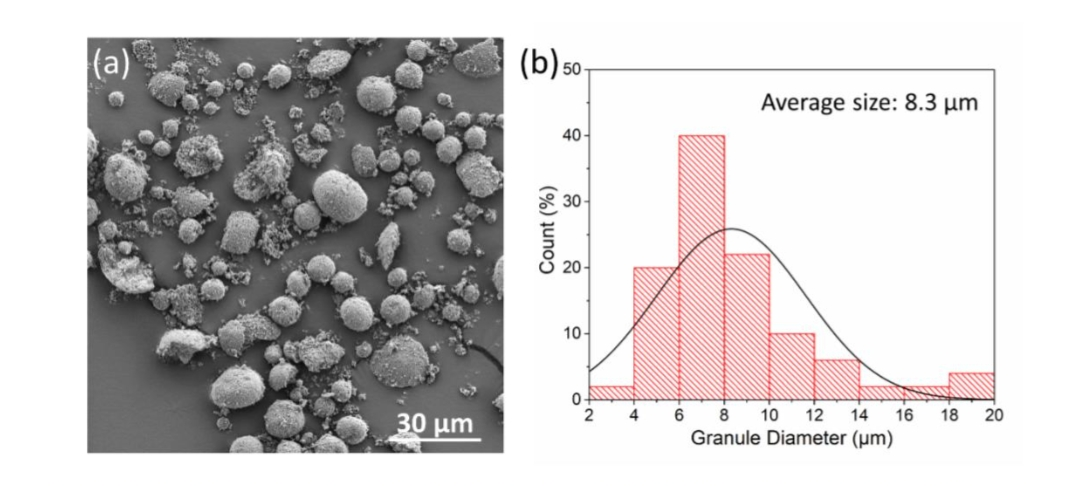

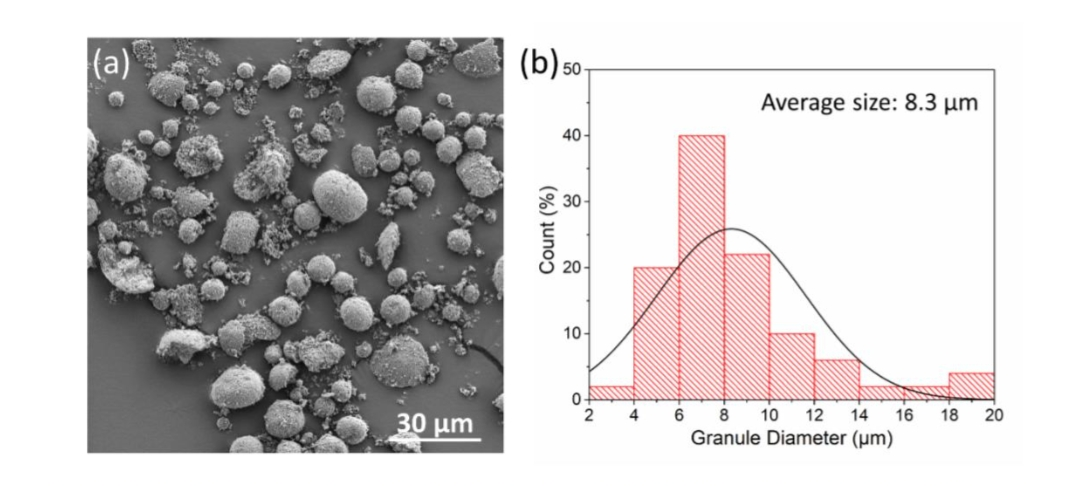

It has been found that particles with a larger size range should be beneficial for the generation of homogenous and dense coatings and excessively large particles will tend to damage the substrate. However, when employing Palas® RBG 1000 aerosol generator to generate aluminum oxide aerosol, the compacted powder is delivered into a rotating dispersing brush and subsequently dispersed from the bristles by a shear stream of carrier gas, resulting in a fraction of the particles of the diameters shown in the graph below. It is obvious that although the particles are still of a large diameter, they have been effective in facilitating de-agglomeration and reducing powder clumping. This achieved increased densification while protecting the substrate from damage.

(a)SEM micrograph and (b) diameter distribution of the spray-dried alumina powders after flowing through the brush-type aerosol generator.

Stabilized Output Palas® Aerosol Generators

Palas® RBG 1000 aerosol generator can offer stable and repeatable dust aerosol at pressures up to 3 bar. Its feedstock reservoirs are pressure-resistant. The available mass flow rate is from 0.04 to 430 g/h, which can meet various test requirements under different mass concentration conditions.

In the process optimisation of alumina coatings, the researchers adjusted the physical properties and recorded different impact velocities to obtain different alumina coatings. The stable dusting capability of the RBG 1000 generator enabled the researchers to obtain reliable experimental data, which resulted in denser coating without visible cracks, improved deposition efficiency and increased adhesion strength, thus contributing to the scientific research.

If you are interested in the technical article “Process optimisation of alumina coatings by modification of powder characteristics in the aerosol deposition method”, please click to register to download the file in pdf format.

Click to register for download

Palas® RBG series of aerosol generator

In 2022, Palas® launched the new RBG series, which greatly improves the performance based on RBG 1000 ISD and other products. This series supports the generation of dust aerosols from powder, pollen, and spores, with a mass flow rate of about 40 mg/h – 800 g/h. Three new aerosol generators RBG professional, RBG basic, and RBG solo from Palas® can meet requirements from research to quality assurance and calibration requirements.

Low-concentration solid particle aerosols produced from dust and powders are required for many applications in research, development, and quality assurance and for the calibration of particle measurement devices. A high level of dispersion constancy is required for those substances to the point of lowest dosing rates. Additionally, good reproducibility during aerosol generation must be guaranteed. The RBG system fulfills these requirements for mass flows between 0.04 up to 800g/h.

Advantages

· Reliability

· High reproducibility for measurements due to very good long-term dosing consistency

· Ideal for dispersion of many non-cohesive dusts

· ReliabilityFlexibility

· Fast adaptation to changing test conditions with different solids containers and dispersion lids

· Wide application range up to 10 bar over pressure and 0.4 bar negative pressure and with different carrier gases

· Fast response

· User friendliness

· Easy to operate due to automatic monitoring of the volume flow and LCD display for all parameters

· Convenient remote control of the RBG System via supplied Palas® software via USB interface

Applications

· Filter testing

· Development of new filter and filter material

· Calibration

· Particle image velocimetry

· Inhalation test

· Mask check

Palas® regularly conducts webinars on a variety of topics to pass on its expertise in aerosol measurement technology, which are presented in detail online by Palas® technical experts and industry scholars from around the world. Register for the webinar and get the information as soon as possible!