In the pursuit of emission reduction, low-emission hydrogen production methods have gradually attracted the scientific research teams’ attention. For example, in a photovoltaic cell with bismuth vanadate (BiVO4) coating, hydrogen production can be achieved by the direct conversion of sunlight. Then, how to make an ideal BiVO4 coating? It’s a challenge faced by researchers.

Palas® RBG 1000 ISD aerosol generator can perform stable aerosol generation under different pressure conditions. It provides reliable test data for researchers when using aerosol deposition (AD) to make BiVO4 coating. Palas® will keep helping people to pursue a low-carbon and environmental-friendly method of hydrogen production in the future.

Aerosol deposition in need of further research

BiVO4 shows light absorption within the visible range of the solar spectrum, which predestines this material for use in the photovoltaic cell’s coating which produces hydrogen. Researchers also tend to make BiVO4 coating in the way of Aerosol Deposition because this way does not produce any undesired impurities or residues that could reduce photoelectrochemical activities. However, obtaining an ideal BiVO4 coating requires comparative experiments under different pressure conditions. Before the stable operation of Palas® RBG 1000 ISD under up-to-3 bar overpressure for this experiment, a systematic investigation to derive the effective feedstock sizes and spray parameter sets for aerosol deposition of BiVO4 was still missing.

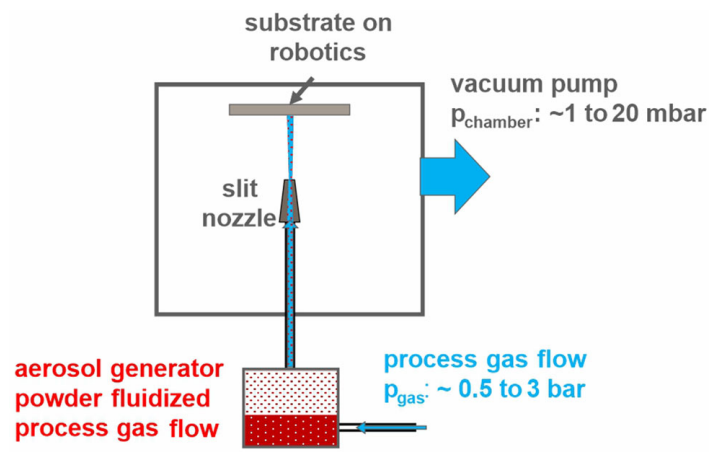

Schematic illustrating the principle of the aerosol deposition method.

In the method of aerosol deposition, the aerosol is produced in an aerosol generator and fed directly into the main process gas stream through a converging nozzle and the gas expansion into a vacuum chamber. Besides, the aerosol can be accelerated to high velocities of up to 350 m/s. The vacuum chamber minimizes the interaction with the surrounding atmosphere and reduces the bow shock effect in front of the substrate, hence preventing the fine powder from being deflected with the gas flow.

During the experiment, specially designed equipment was chosen for ensuring well-defined and reproducible process gas and chamber pressures. The BiVO4 powder was sprayed via aerosol deposition in the original as well as differently-milled states. As the common carrier and process gas, nitrogen was used at gas flows of 10, 20 and 40 l/min, corresponding to process gas pressures of 1.0, 1.3 and 2.1 bar respectively. The base pressure of the vacuum chamber was kept at about 0.3 mbar. Besides, researchers kept the spraying distance up to 30 mm and the substrates passing the aerosol gas stream with a traverse speed of 15 mm/s. Furthermore, the substrates were coated with two layers to explore the most suitable parameter method.

Reliable Palas® aerosol generator

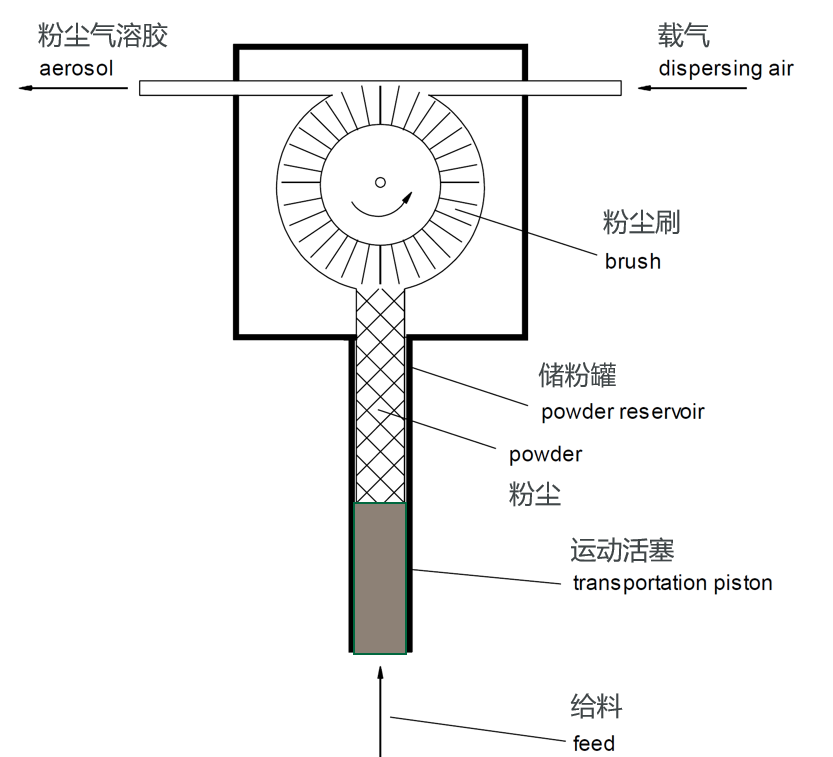

Palas® RBG 1000 ISD can offer stable and repeatable dust aerosol at pressures up to 3 bar. Its feed stock reservoirs are pressure-resistant. The available mass flow rate is from 0.04 to 430 g/h, which can meet various test requirements under different mass concentration conditions.

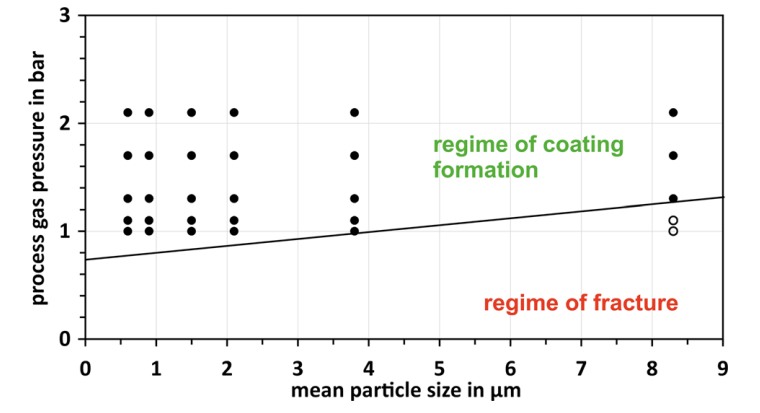

Back to the experiment related to BiVO4 coating, the researchers adjusted the volume flow rate of the nitrogen used by the generator several times to get different BiVO4 coating formation effects. The stable dust generation ability of the RBG generator allowed people to have reliable test data. And it could be concluded that the larger powders need higher gas pressures for successful layer deposition. For most of the powders with various sizes, higher pressures appear to be beneficial for layer formation. In addition, the cyclone types Z1000 and Z500 from Palas® also helped separate undesired particle sizes from the test aerosol. The Palas® instruments worked together for a more stable experiment condition and finally made it.

If you are interested in the technical article “Tuning Aerosol Deposition of BiVO4 Films for Effective Sunlight Harvesting”, please click to register to download the file in pdf format.

New Palas® RBG series of aerosol generator

In 2022, Palas® launched the new RBG series, which greatly improves the performance based on RBG 1000 ISD and other products. This series supports the generation of dust aerosols from powder, pollen and spores, with a mass flow rate of about 40 mg/h – 800 g/h. Three new aerosol generators RBG professional, RBG basic and RBG solo from Palas® can meet requirements from research to quality assurance and calibration requirements.

Advantages

· Overpressure operation up to 10 bar

· Wider mass flow range

· 8 mg/m3 stable mass concentration capacity

· 100 hours of continuous work

· Remote control

Applications

· Test of cabin filter

· Development of new filter and filter material

· Calibration

· Particle image velocimetry

· Inhalation test

· Mask check

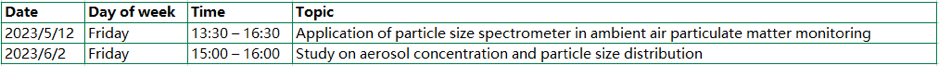

Palas® organizes a series of webinars on various topics to share professional knowledge of aerosol measurement technology. Palas® technical experts and industry scholars from all over the world will give you detailed online explanations. Welcome to register to attend and learn more about the webinars as soon as possible!

Click here to register